Process of precision mold & design engineering

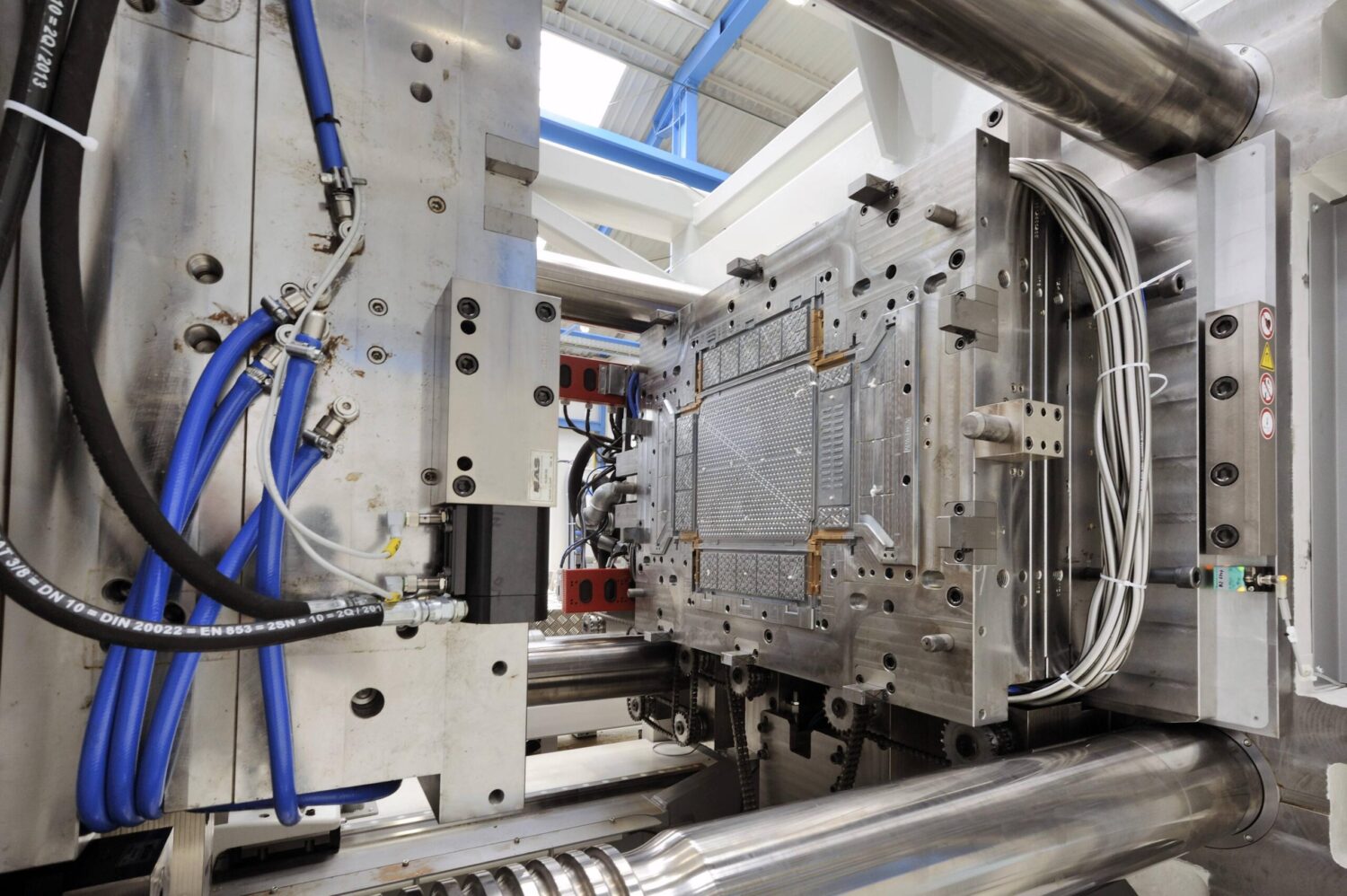

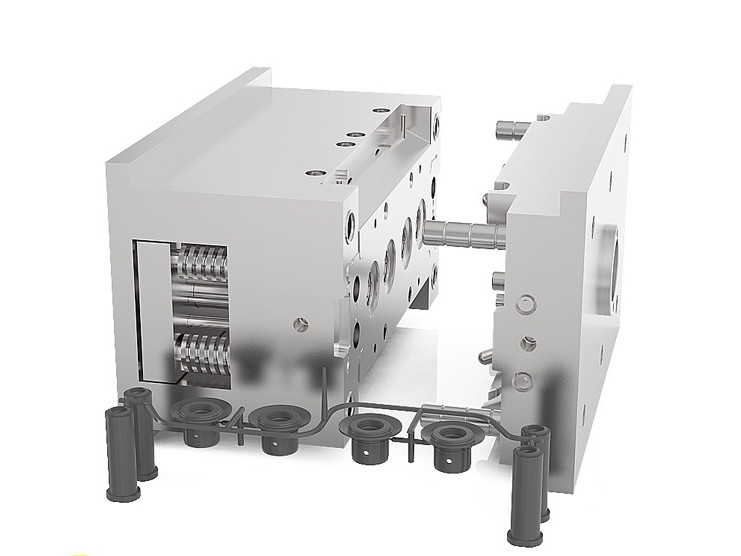

Plastic injection molding is a highly precise manufacturing process which requires precise molds. Usually, the tolerances are.005″ to.001″. Precision molding also requires a consistent temperature control. A temperature controller is a device that balances the heat loss of the plastic material. Water lines are also used to avoid condensation from building up on the mold’s surface as the mold opens. Each plastic has different physical and chemical characteristics, and this determines the quality of the injection molding process.

Process of precision injection molding

Precision injection molding machines are used to produce small parts of various sizes and shapes. They must be designed to withstand high pressure and high temperatures to avoid product deformation. They must also have high accuracy in parting surfaces and cavity sizes. These factors contribute to the precision of the parts produced by these machines. To achieve the highest precision possible, the process should use multiple stages of feedback control.

The process can be performed with most types of polymers, sometimes referred to as resins, including all thermoplastics, some thermosets, and some elastomers. Since 1995, the number of polymers used in injection molding has increased by 750 percent, from approximately 18,000 materials in 1995 to over 7,000 today. This includes new alloys and previously developed materials. Materials are selected based on strength and function requirements of the final part, as well as cost.

The tolerances used in precision injection molding can range from 0.005 to 0.002 inches. To achieve these precise tolerances, consistency in the temperature of the mold is important. The process includes water lines to balance heat loss from the plastic material. Temperature controllers also combat humidity, which causes condensation on the surface of the mold. Each plastic material has its own physical and physico-chemical properties, which also affect the precision of the mold’s process.

Materials used in precision injection molding

Materials used in precision injection molding

There are several factors that affect the precision of plastic parts in the precision injection molding process. One of these is the material used. While polyethylene is the most common resin used for precision molding, there are other materials that are used instead. Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer that can withstand high temperatures and shrinkage. This material also has a low shrinkage rate of less than.006 percent. However, it is not suited for precise molding due to its external properties and low mechanical strength.

The stiffness of the material determines its ability to withstand bending stress. ABS is stiffer than Nylon, but is softer. The weight of the material also has a large impact on the end product. Nylon is heavy, while polyethylene is lightweight. Chemical resistance is another important factor to consider when selecting a plastic material. Materials with better chemical resistance are more suited for a variety of applications.

Among the most common materials used for precision injection molding are acrylic, POM, nylon, fiberglass, and POM. These materials have many advantages, including their low melting point, ease of molding, and resistance to heat, acids, and alkali.

Cost of precision injection molding

One of the key factors affecting the cost of precision injection molding is the materials used. These materials can range in price from modest to expensive.The cost quote you receive will depend on the specifications of your product. In order to save money, make sure your design is as simple as possible. This will help you get the best molding results. Keep in mind that more complex parts require complicated molds and additional steps in the injection molding process. Therefore, you can reduce the cost of molds by eliminating unnecessary features. Likewise, you can save money by omitting cosmetic finishes, which are not essential to the overall look of the product.To get an accurate cost estimate, you can consult XIAOLIN