3D Printing is a modern fabrication process that can create 3D printed objects from a variety of materials. Different methods of 3D printing produce different types of parts. Here is a brief overview of these methods. Some of the most common types are Stereolithography, Fused filament fabrication, and Selective laser melting (SLM).

Selective laser melting (SLA)

Selective laser melting is a process that involves using a powerful laser to fuse layers of powdered particles. Most SLA machines use polymer or nylon-based build materials. However, more advanced machines are capable of fusing other materials with higher melting temperatures. The advantage of SLA over other 3D printing techniques is that SLA parts can be made without support structures and are lightweight. They are also durable and can withstand impact, UV light, water, and chemicals.

Selective laser melting (SLM)

Selective laser melting (SLM) is a process that combines three-dimensional printing with metals. The printer works by heating the metals in layers and melting them selectively. This process produces parts that are nearly net shapes. Additionally, it reduces material waste and increases the efficiency of the manufacturing process.

SLM is a process that is gaining popularity in manufacturing and is ideal for rapid prototyping. The process uses a high-energy laser to fuse metal powder. The metal powder is melted by the laser in layers, and each layer is heated above the melting point of the material.

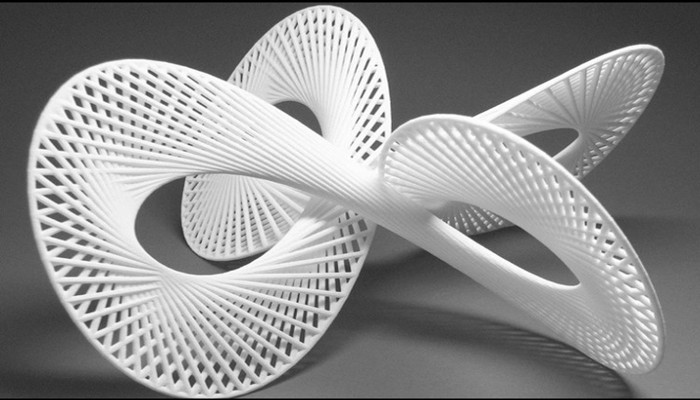

SLM is a versatile process that enables designers to create intricate and complex shapes. It is also great for constructing bionic lightweight structures. Another advantage of SLM is its ability to consolidate assemblies, reducing material and labor costs. In addition, the process improves component properties. Finished parts have a high density and almost pore-free surfaces.

Selective laser melting (SLS)

The SLS 3D printing technology has several advantages for designers. It is lightweight and can print parts that require complex geometries, interior components, and moving parts. The process can also be used to print parts that require multiple elements in one piece. This can increase the design’s efficiency and reduce manufacturing costs.