When it comes to the manufacturing industry, nothing has changed as much as computer numerical control (CNC) machining. The technology has made huge impacts on the sector and is continuing to do so. In this blog post, we will be exploring everything you need to know about CNC Machining. CNC Machining is a computer-driven process for cutting or milling materials with precision accuracy and speed. It allows manufacturers to accelerate production and create more accurate parts than ever before. There are many benefits of investing in CNC Machining from greater efficiency, reduced waste and shorter lead times – all of which help businesses grow faster, retain a competitive edge, increase returns on investment and reduce costs.

What is CNC Machining?

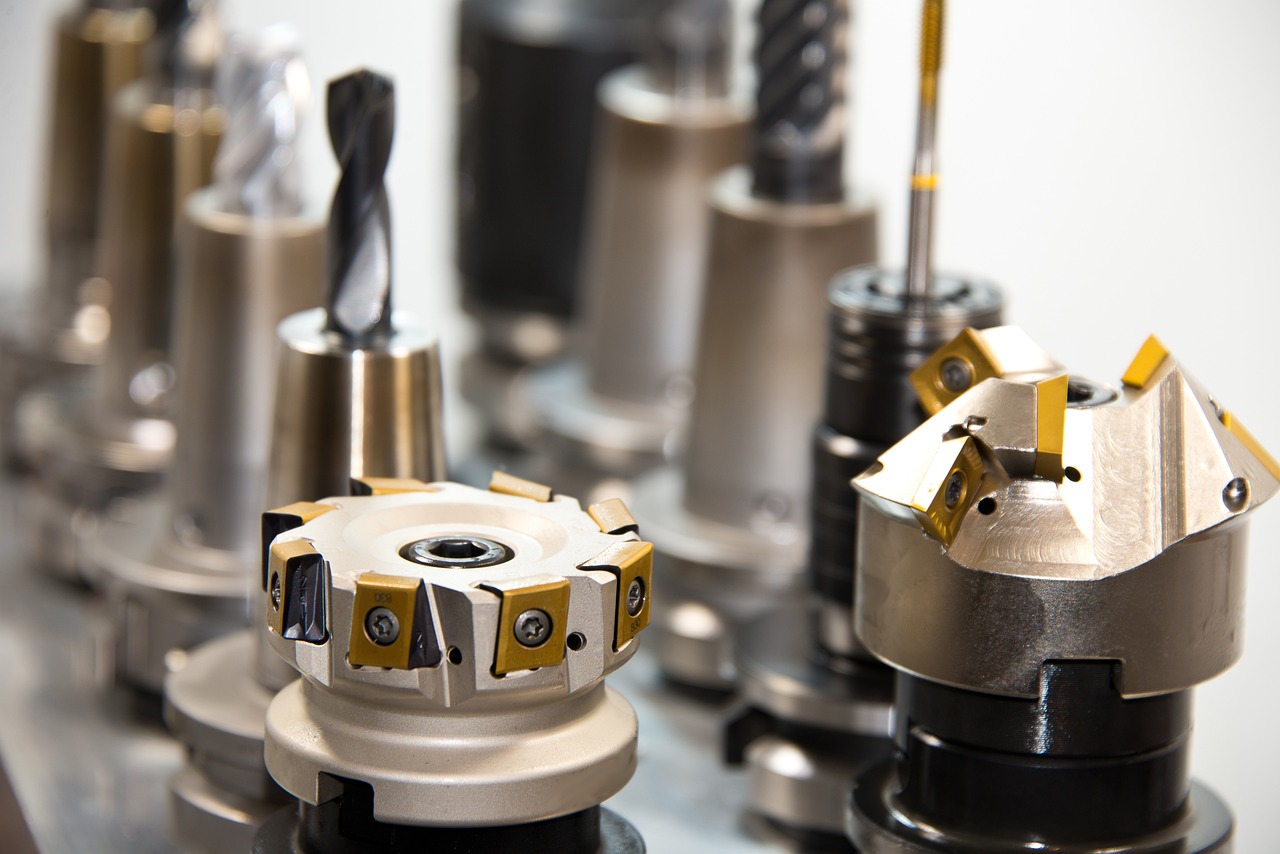

CNC stands for computer numerical control. It is an automated process that includes the design of a product, the production of a part, the programming of the CNC machine and then the creation of the part. CNC and CAD (computer-aided design) work together to create precise, manufactured parts. A CAD system uses Computer Numerical Control to precisely instruct machines about the design of a part. It enables businesses to design precise parts in virtual environments and then create them in the real world. CNC machines are computer-controlled machines that can create precise parts of almost any shape. CNC machining is the process of using computers to control machine tools to make parts out of different materials like metals, plastics and wood. Originally, these machines were programmed with a control board and a paper tape reader. Nowadays, CNC machines are controlled by computer software. CNC machining is highly beneficial to companies that make a lot of products. For example, furniture manufacturing companies that use CNC technology can make several pieces of furniture at the same time and at a fraction of the time it would take for one person to do it by hand. CNC machines can create complex parts with accuracy, speed, and consistency that would be impossible for human workers. Machines can also be programmed to perform a variety of tasks and can be fitted with different tools for different jobs.

Why is CNC Machining so important for manufacturers?

As the manufacturing industry continues to evolve, it is only natural for businesses to look for ways to improve efficiency and increase productivity. With that in mind, manufacturers have been quick to adopt CNC technology and reap the benefits. CNC Machining has raised the bar when it comes to quality and accuracy. It has also accelerated production times and has allowed manufacturers to produce more parts at a lower cost. CNC is a superior technology because it is precise and consistent. Precision is important when it comes to manufacturing because it reduces the risk of defects in the production process. This is especially important when dealing with materials like metals and plastics. CNC allows businesses to produce parts with extreme precision. This high level of accuracy means that parts fit together perfectly and last longer. It also means that they fit with other components and can be used in more applications. CNC also allows companies to produce new designs and experiment with different materials. And it allows manufacturers to make smaller batches of product, which can be beneficial for companies in the long run. CNC machining can be applied across industries, so it’s an important technology for manufacturers to master.

Benefits of Computer Numerical Controlled Machining

– Increased Efficiency CNC machines can make several parts at the same time, which increases productivity and reduces lead time. This means that businesses can make more products in less time, which means increased sales and higher profits. – Consistency and High Quality CNC machines can control pressure, speed and feed rate, which creates the same result every time. This creates parts of high quality and consistency, which is ideal when it comes to manufacturing. – Cost-effective CNC machines are less expensive to run than other manufacturing techniques, which means that businesses can save money in the long run. – No Judgement CNC machines don’t make decisions based on fatigue or human error, which means that they can produce parts 24/7. – No Worker Fatigue CNC machines do not get tired and can work for longer hours. This means that businesses can produce more in less time.

How has CNC changed the manufacturing industry?

Computer numerical control (CNC) machining has changed the manufacturing industry in a number of ways. The technology has transformed the way that companies design, produce and deliver their goods. CNC technology has changed the way that manufacturers design their products, creating virtual mock-ups before ever creating a prototype. This allows businesses to make design changes quickly and easily. CNC manufacturing has made production more efficient. It has also allowed manufacturers to use different materials and create products that are more complex than ever before. CNC technology has also made it easier to manufacture goods in large batches. This is because the technology and design can be replicated by other manufacturers without having to go through the design process again. CNC has also led to the growth of outsourcing. This is because large companies can outsource their production and receive their goods faster. Smaller businesses can also benefit from outsourcing because they can use CNC technology to produce higher-quality goods faster than ever before.

Key takeaways

CNC Machining has changed the manufacturing industry by being more efficient, consistent and cost-effective, making new designs and being able to use different materials. It has changed the way that companies design, produce and deliver their goods. CNC technology has changed the way that manufacturers design their products, creating virtual mock-ups before ever creating a prototype. This allows businesses to make design changes quickly and easily. CNC manufacturing has made production more efficient. It has also allowed manufacturers to use different materials and create products that are more complex than ever before. CNC technology has also made it easier to manufacture goods in large batches. This is because the technology and design can be replicated by other manufacturers without having to go through the design process again. CNC has also led to the growth of outsourcing. This is because large companies can outsource their production and receive their goods faster than ever before.

If you are looking for a production factory for cnc products, then try XIAOLIN now.