In a world when to develop new products, the combination of prototyping and on-demand manufacturing has made the development of new products possible. Now, anyone with an idea can bring their dream to life. With the help of on-demand manufacturing, even the smallest details can be reproduced quickly and cheaply.

In terms of cost, the most obvious cost-saving advantage of on-demand manufacturing is the lack of minimum order quantities. Since a company may only need a small number of molded parts, on-demand manufacturing is a great option. It allows a company to scale as their needs change.

Another advantage of on-demand manufacturing is its speed and flexibility. Customers can request a prototype and have it manufactured in a matter of days. This process is a significant time and cost-saving for the manufacturer. Traditional manufacturing, on the other hand, requires elaborate logistics systems, an elaborate storage system, and a comprehensive sales network. It also requires a great deal of maintenance and monitoring of transportation infrastructure.

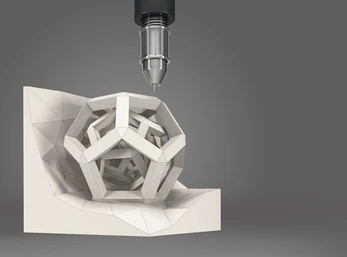

Rapid prototyping is a growing trend in the manufacturing industry. In the past, the only options for rapid prototyping and on-demand manufacturing were traditional manufacturing methods. These methods now use 3-D scanning or additive manufacturing (aka 3D printing). This process uses layers of materials to build a part in three-dimensional form.