Gauge Plastic Parts Services

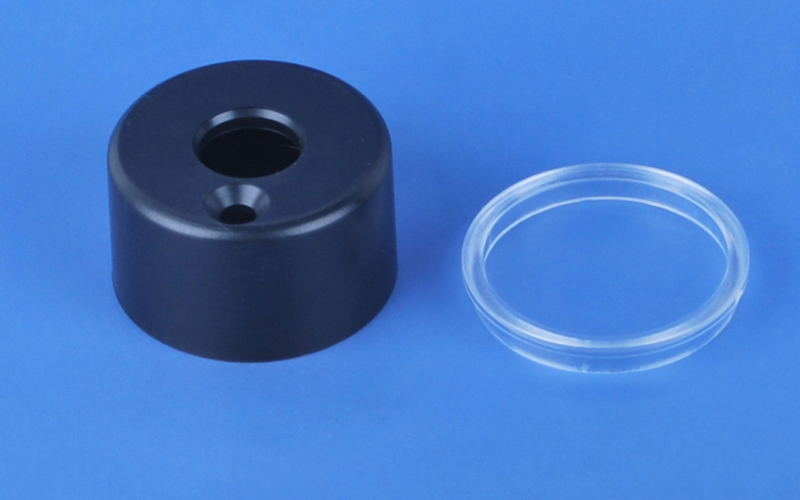

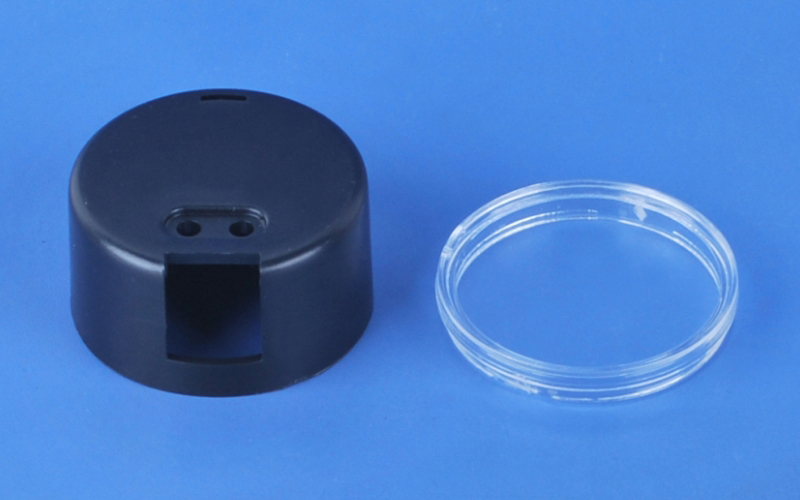

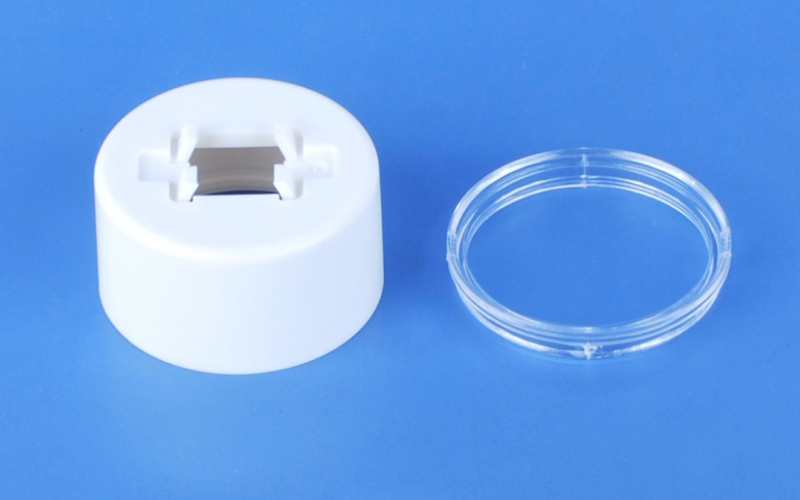

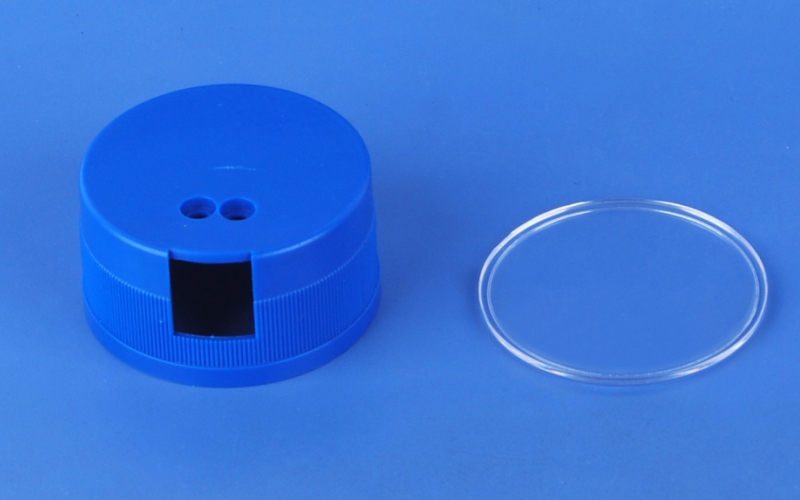

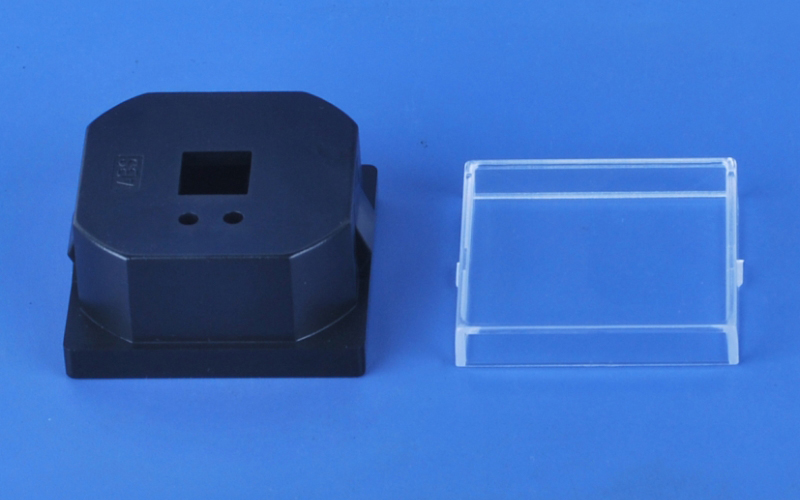

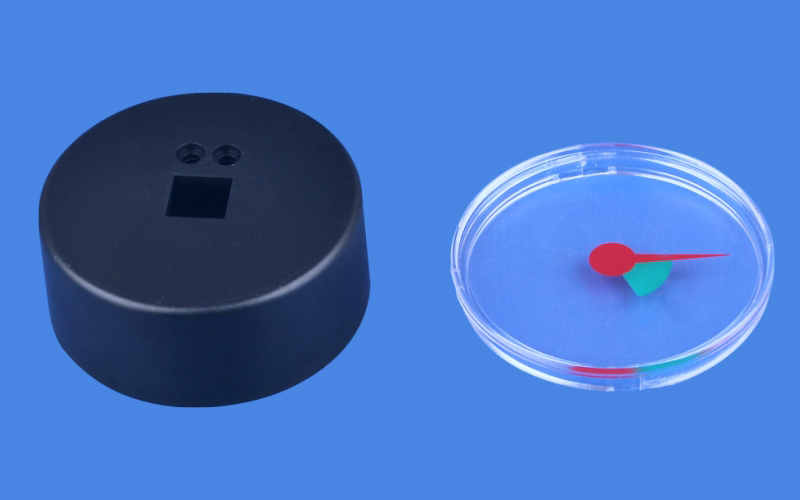

Our factory provides one-stop service from design and development, mold manufacturing and production. Our factory mainly produces all kinds of pressure gauge casings, transparent covers, plastic lenses, protective casings, plastic caps, pointers, dials, sealing rings and more than 1,000 products of different specifications. Our factory has scientific and technological production, strict quality requirements, and innovative design concepts, which have won the trust and praise of our customers.

Pressure Gauge -Plastic Case

A pressure gauge with a plastic case is a type of pressure measuring instrument that has a protective outer casing made from plastic materials. This plastic exterior is often designed to provide enhanced durability, protection from environmental factors and sometimes, chemical resistance. They are typically used in various industries such as manufacturing, HVAC, automotive, and water, air, steam system,pneumatic system .

Some key features of a pressure gauge with a plastic case may include:

1. Durability: The plastic case offers enhanced durability, protecting the gauge from physical damages and reducing the chances of breakage.

2. Corrosion resistance: A plastic case can offer better resistance to corrosion, chemicals, and moisture compared to traditional metal-based cases. This makes it suitable for use in harsh environments or applications involving corrosive substances.

3. Lightweight: Plastic cases are typically lighter than their metal counterparts. This can make them easier to handle, install and can contribute to lower shipping costs.

4. Cost effectiveness: Plastic cases can often be cheaper than metal cases, making them an appealing option for cost-sensitive applications.

5. UV resistance: Some plastic cases are designed to resist UV damage, which can make them suitable for outdoor installations or applications exposed to sunlight.

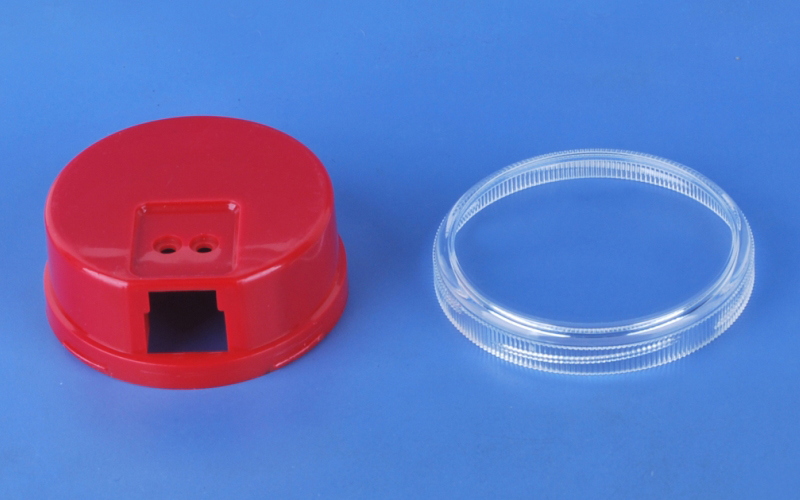

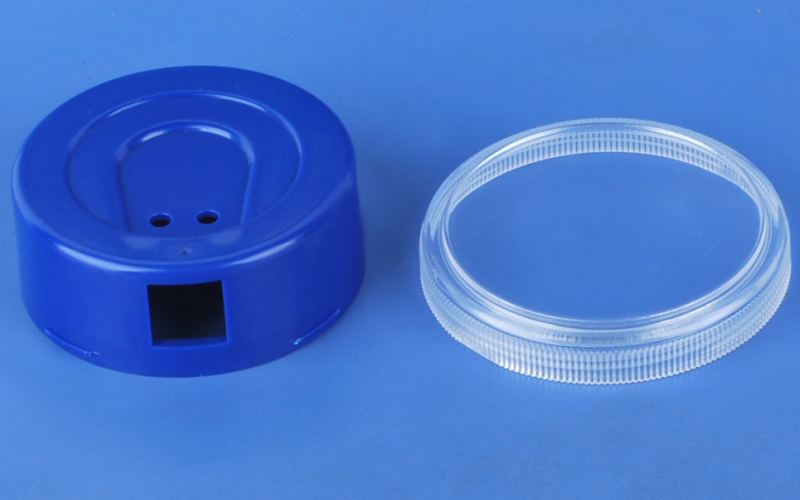

6. Aesthetics: Plastic cases can be produced in a variety of colors and finishes, providing more options to suit different applications and preferences.

When selecting a pressure gauge with a plastic case, it is essential to consider factors such as the pressure range, accuracy, connection type, and environmental conditions, in addition to the type of material being used for the case.

Provide 100 different pressure gauge casings and support customization

Our plastic pressure gauge parts are made with precision and care, ensuring that they meet the highest standards of quality. As leading manufacturers and suppliers in the industry, we take pride in our products and strive to exceed your expectations. Trust us for all your plastic pressure meter part needs.We have 100 different pressure gauge plastic cases, the following is a part of XIAOLIN pressure gauge plastic case display, if you want to see more case pictures, please contact us or Click here to browse more.

Pressure Gauge Plastic Case Materials

Choosing the right plastic material for your pressure gauge parts is crucial to their durability and longevity. With our expert guidance, you can choose the perfect plastic material that fits your needs and ensures that your pressure gauges function at their best. Trust us to provide you with high-quality plastic pressure gauge parts that exceed your expectations.The following are commonly used pressure gauge plastic case materials

1. ABS (Acrylonitrile Butadiene Styrene) case pressure gauges: These gauges have a durable plastic casing and are commonly used for air, water, and non-corrosive applications.

2. PVC (Polyvinyl Chloride) case pressure gauges: PVC pressure gauges have a durable, corrosion-resistant plastic casing and are suitable for use in water treatment, chemical processes, and other applications where exposure to chemicals or corrosive materials is a concern.

3. PTFE (Polytetrafluoroethylene) or Teflon case pressure gauges: These gauges have excellent chemical resistance and are suitable for use in highly corrosive environments or in applications where the process media may be reactive.

4. Polycarbonate case pressure gauges: Polycarbonate gauges have good impact resistance and are suitable for use in applications where physical shock or impact may be a concern.

Machined Parts on Your Schedule

Are you in search of a reliable, high-quality supplier for plastic parts for your pressure gauges? Look no further! Our factory, equipped with 30 state-of-the-art injection molding machines, specializes in producing top-notch plastic components designed specifically for pressure gauges. As a leading manufacturer in the industry, we understand the importance of precision and performance when it comes to pressure gauge components. That’s why we dedicate ourselves to meet the highest quality standards, ensuring that every part we produce is ready to serve its purpose effectively in your pressure gauges. Beyond our technical expertise, our dependable reputation and commitment to timely delivery will guarantee your satisfaction from start to finish. Place your trust in us, and together, we’ll elevate your pressure gauge production to new heights.

Why Choose Us for Custom Gauge Plastic parts

1. Quality: We use high-quality materials and advanced manufacturing processes to ensure that our plastic parts meet the highest standards of quality.

XIAOLIN plastic cover has high transparency, no blemishes, no spots, no texture on the surface, and it is as smooth as a mirror. And the plastic cover has strong impact resistance, and will not break during machine assembly. We have a high-demand quality inspection team, and every product that leaves the factory has been inspected.

2. Experience: We have years of experience in the plastic parts industry, and we use that experience to deliver the best possible products and services to our customers. Our factory have all kinds of pressure gauge casings, transparent covers, plastic lenses, protective casings, plastic caps, pointers, dials, sealing rings and more than 1,000 products of different specifications.

3. Customization: We offer custom solutions to meet your specific requirements, ensuring that you get exactly what you need.

4. Fast Turnaround: Our manufacturing process is designed to deliver your products quickly, without sacrificing quality.

5. Competitive Pricing: We offer competitive pricing on all of our custom gauge plastic parts, helping you to save money without sacrificing quality.

Pressure Gauge Plastic Parts FAQs

Pressure gauge plastic parts are commonly made from thermo-plastic materials such as polycarbonate, ABS, and polypropylene.

A pressure gauge plastic cover is used to protect the pressure gauge from external damage, including impact or exposure to harsh environments, such as extreme temperature or chemicals.

Pressure gauge plastic cases can be made water-resistant by utilizing sealing technologies, such as O-rings, gaskets, or silicone caulk.

The resistance of pressure gauge plastic parts varies based upon the specific material and construction. However, some thermo-plastic materials, such as polycarbonate, have high impact and pressure resistance.

Yes, we support any plastic parts customization service.

You can contact our customer service to get the electronic product manual.

Yes, because the two of them are different, with different fields of expertise. The manufacture of pressure gauge plastic parts is a joint venture, so it is separated.

Additional Links and Resources

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …