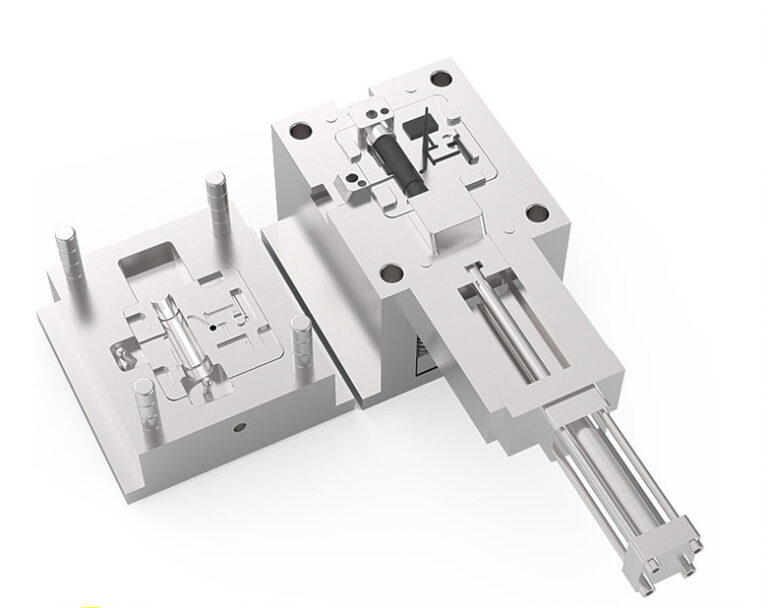

Custom Mold & Moulding

There are several factors to consider when selecting the right steel for a plastic mold. First of all, the type of plastic you plan to use is essential, as is the product’s shape and dimensions. You should also consider quality and appearance. Once you have these details, you can choose the appropriate steel for your mold. Other factors to consider are production scale, cost, and the conditions of the mold-making process.

The cost of plastic mold making varies depending on the type of plastic mold that you need and the size of your parts. The materials used to make the mold, the complexity of the parts and the quantity that you expect to sell will determine the price. We will suggest the best solution for your parts based on these variables.

Mold&mould Steels

| 8170 | VIKING | SKD61 |

|---|---|---|

| P20 | H13 | PS |

| 2738.TS | NAK80 | TDAC |

| 420 | S-136 | 45# |

If you have requirements for the number of products produced by the mold, we can also make different processes for the hardness of the mold, general ordinary mold can produce about 100,000 to 300,000 products, the mold with high hardness can produce 1 million to 3 million products, do you need an economic mold or a high hardness mold? Tell us and we will provide the best solution.

Plastic Mold Surface Treatment

The type of surface treatment applied to a plastic mold can determine the performance of the finished product. The type of surface treatment is important because it will influence the type of material used and the tooling design. It will also determine the amount of wear that will occur. Ideally, the surface treatment is decided early on in the design process.

At present, the commonly used surface treatment methods for plastic moulds are nitriding, electroplating, grained leather,polished surface and sandblasting.

Among them, nitriding and electroplating are the methods to improve the life of the mold, while grained leather and sandblasting are the surface decoration methods of the mold.

| VERTICAL FACES | 0.5° |

| MOST SITUATIONS | 2° |

| MINIMUM FOR SHUT OFF | 3° |

| MINIMUM FOR LIGHT TEXTURE (PM-T1) | 3° |

| MINIMUM FOR LIGHT TEXTURE (PM-T2) | 5°+ |

Plastic materials

We can offer more than 100 different thermoplastic materials. If you are looking for alternative materials, please review our resin substitution guide for ABS, PC, PP,POM,PA,PBT,PPS and other common plastics, or contact us.

- ABS

- PP

- PBT

- PA6

- PS

- PPO

- PPS

- TPU

- PET

- HDPE

- PC/ABS

- PC/PBT

- PVC

- AS

- PA12

- MDPE

- LDPE

- PEI

- PMMA

- PPE

- EVA

- PC/PMMA

- PA66

- POM

The Thick Wall Injection Molding Process

The injection molding process can produce a variety of molded parts with varying wall thicknesses. The wall thickness of a part depends on the material that is used to make it. The thickness of the wall is an important factor for the final product’s appearance, because it affects the part’s overall function and appearance. Other factors that affect wall thickness include the flow rate and yield of the part, as well as the stiffness and strength of the material.

The wall thickness of a part can have a significant impact on its price and quality. Having too thick of a wall can lead to issues with filling cavities and may result in bubbles and warpage on the surface. A thick wall also increases the cost of the part because it requires longer cooling times, which can increase the part’s cycle time and cost.

The wall thickness of a plastic part is important when designing a plastic product. The wall thickness of a part will determine how smoothly it flows through the mold during the cooling phase. A thicker wall allows more material to flow through the mold, but a thin wall restricts the flow and can cause sinking, warping, and non-filling in the part.

Another consideration is the design of the injection mold. It is important to design a mold with a parting line, which is where two halves of the mold will meet. For some applications, this may be an obvious choice, but for others, it can be tricky. The first step is to decide which direction the parting line will run in, as this will determine the direction of the opening of the mold.

Wall Thickness

| MATERIAL | RECOMMENDED WALL THICKNESS |

|---|---|

| ABS | 1.143mm - 3.556mm |

| Acetal | 0.762mm - 3.048mm |

| Acrylic | 0.635mm - 12.7mm |

| Liquid Crystal Polymer | 0.762mm - 3.048mm |

| Long-Fiber Reinforced Plastics | 1.905m - 25.4mm |

| Nylon | 0.762mm - 2.921mm |

| Polycarbonate | 1.016mm - 3.81mm |

| Polyester | 0.635mm - 3.175mm |

| Polyphenylene Sulfide | 0.508mm - 4.572mm |

| Polypropylene | 0.635mm - 3.81mm |

| Polystynene | 0.889mm - 3.81mm |

| Polyurethane | 2.032mm - 19.05mm |

Since we create the mold for your components using an automated CNC milling technique, some part corners will have a radius rather than a crisp edge. The resulting radii are established before the mold is milled, however this normally does not necessitate changing your model.

A Team Of Mold Making Experts Working For You

In order to assist you study, analyze, and develop your product design so that it complies with the actual production process, we will create a quick prototype for you.

● High-quality Mold Materials

Choosing high-strength mold steel to manufacture the main body of the mold can obtain perfect precision and details from the precision CNC Machining process, and effectively extend the service life of the mold. In XIAOLIN, our default mold service life is 300.000 times-500.000 It can run several million times through reasonable maintenance and maintenance.

● Reasonably Set The Feeding Method Of The Mold

Allow the material to fill the mold cavity without obstacles to ensure that the product will not have defects. For some appearance parts, a smooth surface is an important factor in obtaining market value. We will use very small pinhole feeds. There are no traces on the surface of the product, and it is hidden on the surface of the product installation part.

● Reasonably Set The Position Of The Thimble And The Ejection Method

When the product is in the mold, it is relatively soft at high temperature, and the unreasonable ejection method will leave a mark on the surface of the product. This problem is irreversible, but the defect can be compensated by hiding and reducing the cross section of the ejector pin. XIAOLIN Very good at solving such problems.

● Reliable Repair And Maintenance

We provide comprehensive after-sales maintenance services for customers with different needs.

Many times buyers will choose our in-house injection molding factory to produce products. We will provide free mold maintenance and repairs.

The Latest from Xiao Lin Blog:

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …