Material Comparison Guide

Research materials to see which options best fit your needs.

Our experienced sales and technical teams are available to assist you with material selection challenges.

Plastic Injection molding POM

What is Material POM?

POM is a type of thermoplastic that is created by reacting anhydrous formaldehyde with alcohol. The resulting hemiformal is then heated to release formaldehyde, which is polymerized by anionic catalysis. Some types of POM are polymerized, while others are not.

The physical and chemical properties of POM make it a popular choice for parts that require a low level of resistance. It is also heat resistant and does not deform easily, unlike other thermoplastic materials. It also has good electrical insulation and a low rate of moisture absorption. It is also strong enough to withstand impact and sliding.

POM is a high-volume engineering plastic with good mechanical properties and is commonly used in consumer electronics and automotive components. It is also an excellent choice for CNC machining. POM has similar properties to PP, so it is a versatile material for many different applications. It is easy to machine and has the same density as PP.

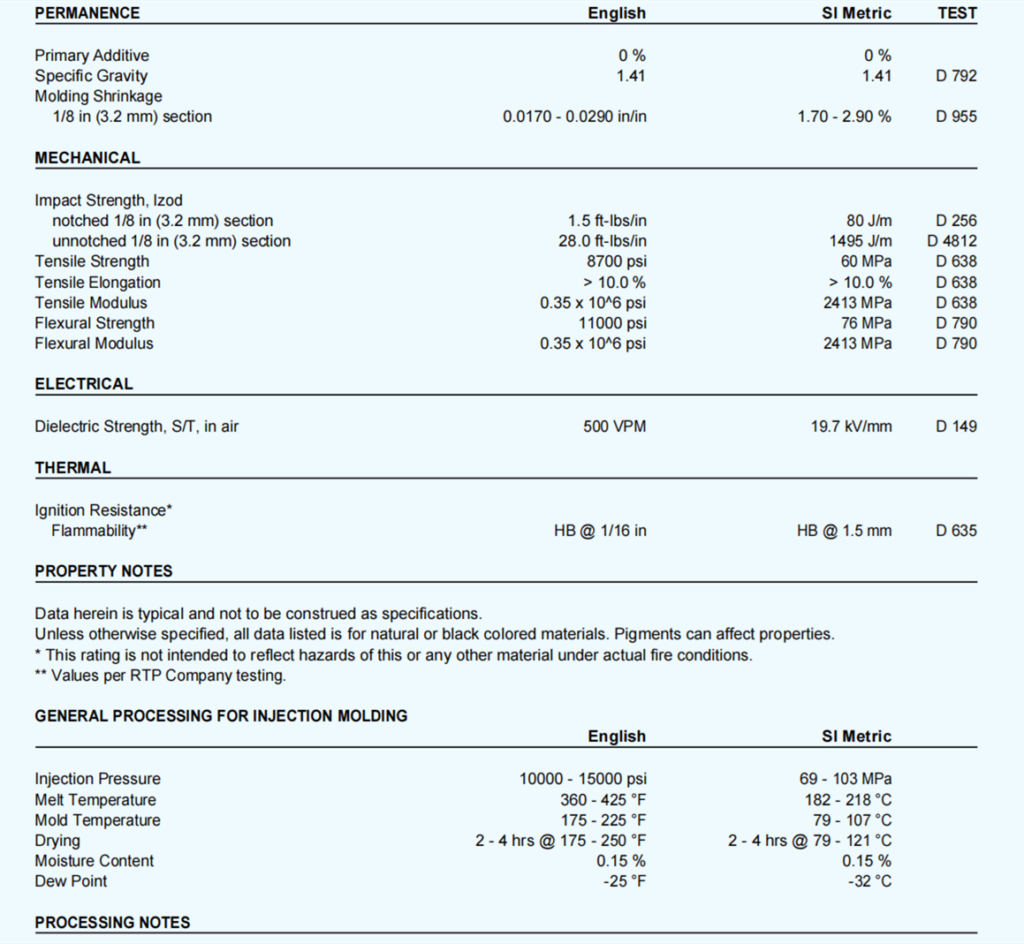

PROPERTIES TABLE OF POM

The table data is for reference only, if the plastic type is different and it has different data.

Injection Molding Material Selection

The process of plastic material selection is an integral part of the product design process. By choosing the right material for your application, you can be confident that the product will meet your expectations for quality, cost, and performance. Furthermore, you will save time and money on manufacturing because you will not have to scrap any parts.

We can offer more than 100 different thermoplastic materials. If you are looking for alternative materials, please review our resin substitution guide for ABS, PC, PP,POM,PA,PBT,PPS and other common plastics, or contact us.

Material

- PET

- HDPE

- PC/ABS

- PC/PBT

- PVC

- AS

- PA12

- MDPE

- LDPE

- PEI

- PMMA

- PPE

- EVA

- PC/PMMA

- PA66

- POM

- ABS

- PP

- PBT

- PA6

- PS

- PPO

- PPS

- TPU

Our POM Product Cases

Material: POM Black

Material:POM Black

Material: Gearwheel POM White

Material: Gearwheel POM Blue

Material: gearwheel pom blue

How Does Plastic Injection Molding Work?

Plastic injection molding is a process in which plastic pellets are formed and injected into molds to form the desired shape. The plastic melts in a chamber and reaches a specified temperature, so the injection time has to be calculated correctly. Once the desired shape is achieved, the plastic pellets are cooled, and the mold is opened. An ejection bar is then used to force the solid plastic part out of the open cavity.

Additional Links and Resources

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …