Material Comparison Guide

Research materials to see which options best fit your needs.

Our experienced sales and technical teams are available to assist you with material selection challenges.

What is Material PC/ABS?

If you are wondering what is Material PC/ABS, you have come to the right place. In this article, you will find out everything you need to know about the material and its properties.To make the right decision, it is important to know the properties of the material you choose.

Applications

Polycarbonate/acrylonitrile butadiene-styrene (PC/ABS) is a material used in the production of servers and other electronic equipment. The demand for this material is growing, thanks to applications in storage, small and medium enterprises, and the growing use of technology in information and communications.

PC/ABS is a versatile thermoplastic material that combines the mechanical and heat properties of ABS with the processability of polycarbonate. Its molecular weight and thermoplastic additives influence its properties.PC/ABS is a blend of ABS and Polycarbonate, which gives it high heat resistance. It also has excellent tensile and impact strength. The polycarbonate content provides for easy processing.

Material PC/ABS is a combination of two common plastics, Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate (PC). The combination of the two materials offers the flexibility of ABS with the heat and impact strength of PC.

Applications of PC/ABS range from medical devices and aerospace to consumer products. Because of its excellent combination of mechanical properties and ease of processing, this material is used in a wide range of industries. It is commonly used in automotive exterior components, electrical housings, and other industrial and medical applications. For consumer applications, PC/ABS can be used for computer housings, monitor bezels, and business equipment housings. This material is also a great choice for parts that must meet UL V0 standards.

Chemical resistance

A slightly amorphous thermoplastic, PC/ABS is non-toxic and flame resistant. It is also resistant to acids and oxidizing agents. In contrast, ABS is not resistant to ketones or low molecular weight solvents. Despite its great properties, PC/ABS is not indestructible. Nevertheless, it can withstand some exposure to corrosive elements.

Chemical resistance is important when evaluating a material’s suitability for a specific application. Chemical resistance depends on several factors, including temperature, driving force concentration, duration, and mechanical load. You can check the chemical resistance of a material by looking at the Chemical Resistance Chart.

Flexural strength

The flexural strength of a material is a measurement of its ability to resist deformation under a load. This strength is generally reported at 5% deformation in the outer surface. The flexural strength of PC/ABS is around 9800 psi / 68 MPa, making it an excellent material for bending and snap-fitting components.

Another test to measure flexural strength is the tensile modulus of a material. This is a single-point test where a pendulum with a specific weight at one end strikes a specimen. The loss of energy is measured and is used to determine the toughness and strength of a material. The tensile strength of PC/ABS is slightly higher than that of ABS.

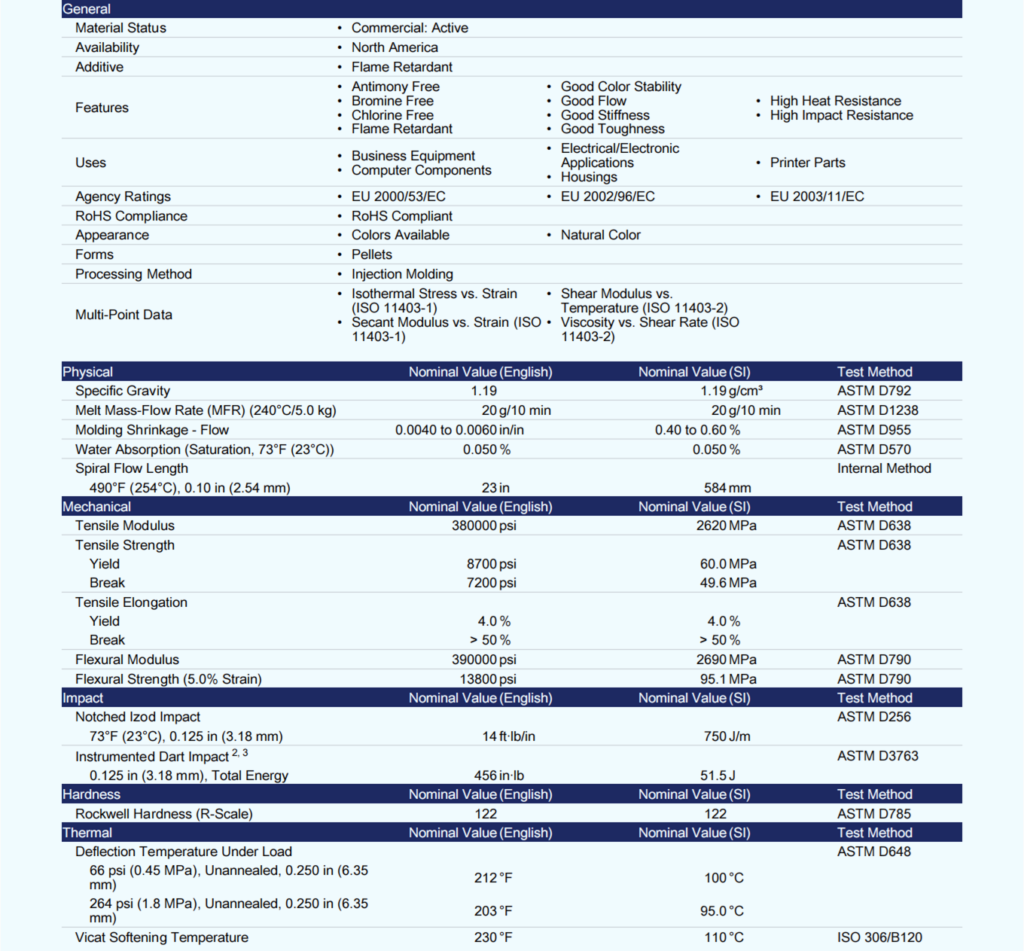

PROPERTIES TABLE OF PC/ABS

The table data is for reference only, if the plastic type is different and it has different data.

Injection Molding Material Selection

The process of plastic material selection is an integral part of the product design process. By choosing the right material for your application, you can be confident that the product will meet your expectations for quality, cost, and performance. Furthermore, you will save time and money on manufacturing because you will not have to scrap any parts.

We can offer more than 100 different thermoplastic materials. If you are looking for alternative materials, please review our resin substitution guide for ABS, PC, PP,POM,PA,PBT,PPS and other common plastics, or contact us.

Material

- PET

- HDPE

- PC/ABS

- PC/PBT

- PVC

- AS

- PA12

- MDPE

- LDPE

- PEI

- PMMA

- PPE

- EVA

- PC/PMMA

- PA66

- POM

- ABS

- PP

- PBT

- PA6

- PS

- PPO

- PPS

- TPU

Our PC/ABS Product Cases

Material: PC/ABS Black

Material:PC/ABS Black

Material: PC/ABS Black

Material:PC/ABS Black

Material: PC/ABS Black

How Does Plastic Injection Molding Work?

Plastic injection molding is a process in which plastic pellets are formed and injected into molds to form the desired shape. The plastic melts in a chamber and reaches a specified temperature, so the injection time has to be calculated correctly. Once the desired shape is achieved, the plastic pellets are cooled, and the mold is opened. An ejection bar is then used to force the solid plastic part out of the open cavity.

Additional Links and Resources

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …