Material Comparison Guide

Research materials to see which options best fit your needs.

Our experienced sales and technical teams are available to assist you with material selection challenges.

What is Material LDPE?

LDPE is a thermoplastic polymer derived from ethylene. The process starts by producing small molecules, known as fractions. These fractions are then reacted to produce the desired thermoplastic. Several methods are used to produce LDPE, including stirred autoclave and tubular routes. The latter is increasingly popular because it provides a high ethylene conversion ratio.

LDPE Environmental friendliness

Material LDPE is an environmentally friendly material. The properties of LDPE include high foaming and tensile strength. In addition, it is easily processed, produces low-odour foams and does not produce any waste products or water. This makes it a good material to use in foaming agents.

LDPE is an affordable thermoplastic material that is used for a variety of applications, including food containers and plastic packaging. Its flexibility and low water absorption make it a desirable material for water-related applications, such as insulation on electrical wires. LDPE can also be recycled. It is widely used in a variety of packaging, including plastic bags, juice containers, and toy packaging.

LDPE is easy to work with and is suitable for injection moulding and film moulding. Its versatility allows it to be used to create anti-slip, anti-bacterial, flame-retardant, and anti-static products. One of the main challenges facing recycling facilities is cleaning plastic packaging and ensuring it is free of contaminants.

LDPE properties

LDPE is one of the most widely used thermoplastic materials in the world. It is a semi-crystalline polymer that is formed by the polymerization of ethylene. Its unique properties include a high degree of short and long-chain branching, reduced intermolecular forces, and improved ductility. These properties make it the preferred material for many applications and technologies. The polymer has been in production since 1939, and today is used in a wide range of everyday items.

Both LDPE and HDPE have similar properties, but LDPE is more flexible and has a lower density than HDPE. LDPE is also less brittle than HDPE and has a lower melting point. Both types of plastic have high strength, but LDPE has a lower tensile strength. Moreover, both materials are recyclable.

The addition of graphene to LDPE improved MFR and tensile strength. However, the addition of graphene did not influence the crystallinity of LDPE. However, it did influence its viscosity.

LDPE uses

Low-density polyethylene is a versatile, cheap plastic that is used widely in a number of applications. Because of its low water absorption, this thermoplastic is a good choice for water-related applications. This thermoplastic can also be heat-sealed, making it an ideal choice for pharmaceutical packaging. It is also very flexible, making it ideal for flexible goods.

LDPE is used in a variety of everyday products, such as shopping bags, juice boxes, toys, and even electrical wire insulation. Its high impact resistance makes it an excellent choice for these applications. In addition to LDPE bags, it is also used for other products, such as plastic cereal box liners.

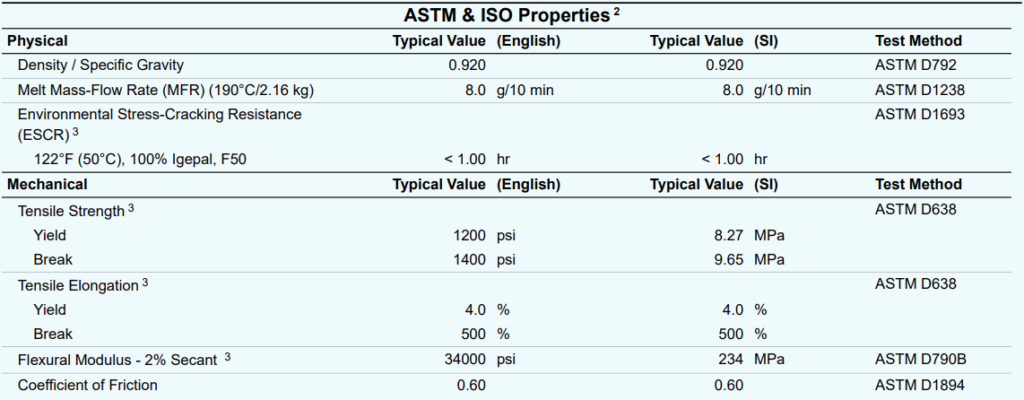

PROPERTIES TABLE OF LDPE

The table data is for reference only, if the plastic type is different and it has different data.

Injection Molding Material Selection

The process of plastic material selection is an integral part of the product design process. By choosing the right material for your application, you can be confident that the product will meet your expectations for quality, cost, and performance. Furthermore, you will save time and money on manufacturing because you will not have to scrap any parts.

We can offer more than 100 different thermoplastic materials. If you are looking for alternative materials, please review our resin substitution guide for ABS, PC, PP,POM,PA,PBT,PPS and other common plastics, or contact us.

Material

- PET

- HDPE

- PC/ABS

- PC/PBT

- PVC

- AS

- PA12

- MDPE

- LDPE

- PEI

- PMMA

- PPE

- EVA

- PC/PMMA

- PA66

- POM

- ABS

- PP

- PBT

- PA6

- PS

- PPO

- PPS

- TPU

Our LDPE Product Cases

Material: LDPE White

Material: LDPE Pink

Material: LDPE White

Material: LDPE Dark Grey

Material: LDPE Translucent

How Does Plastic Injection Molding Work?

Plastic injection molding is a process in which plastic pellets are formed and injected into molds to form the desired shape. The plastic melts in a chamber and reaches a specified temperature, so the injection time has to be calculated correctly. Once the desired shape is achieved, the plastic pellets are cooled, and the mold is opened. An ejection bar is then used to force the solid plastic part out of the open cavity.

Additional Links and Resources

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …