Injection Molding Service

Digital manufacturing for plastic prototypes and on-demand production parts. Request an injection molding quote today.

1.4 Million

Parts molded each month

10,00+

Product developers served

100+

Plastic and elastomeric materials

Injection Molding Processes

We have 15+ injection molding machines from 80T to 2000T in factory that can produce common size injection molded parts. The tonnage calculation/clamping force is one of the key factors for quality and cost. It keeps the tooling closed during the injection process. The higher tonnage, the higher weight of tooling it can keep.

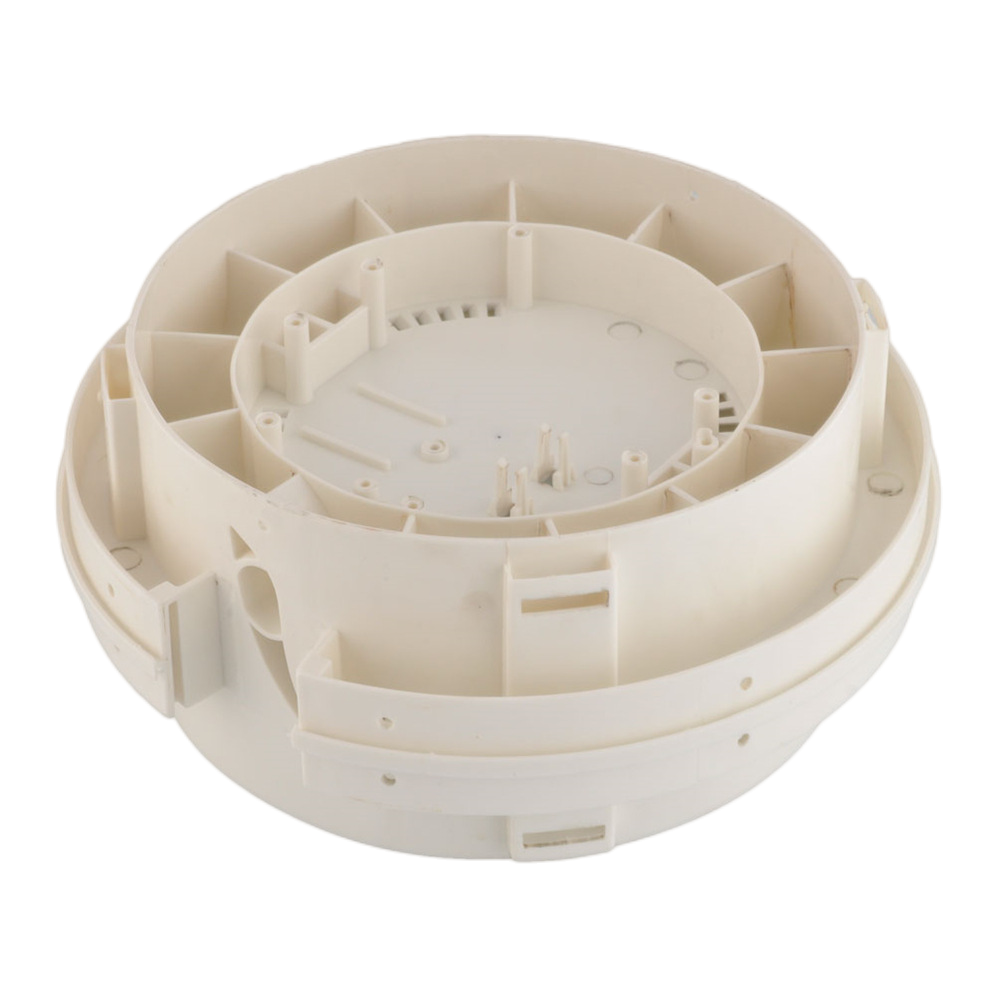

Plastic Injection Molding

In the manufacturing process known as plastic injection molding, resin in a barrel is heated until it melts, at which point it is shot into a mold to create a finished thermoplastic item suitable for production.

Overmolding & Insert Molding

When designing a part, it’s important to consider the process of overmolding or insert molding. Overmolding can improve part manufacturability, while insert molding can improve aesthetic appearance. Using these processes can also reduce overall production time.

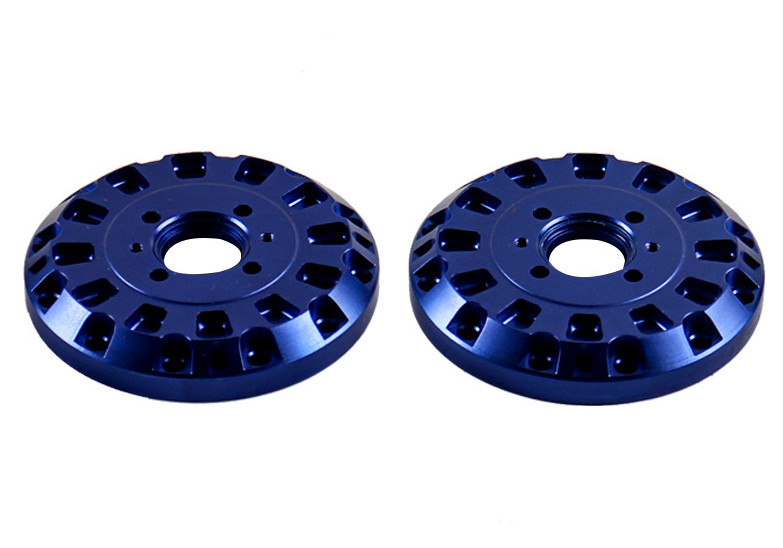

Precision injection molding

Precision injection molding is a manufacturing technique that produces high-quality plastic parts that can replace metal ones. This type of manufacturing process uses various types of polymer materials to create parts such as gears, housings, and frames.

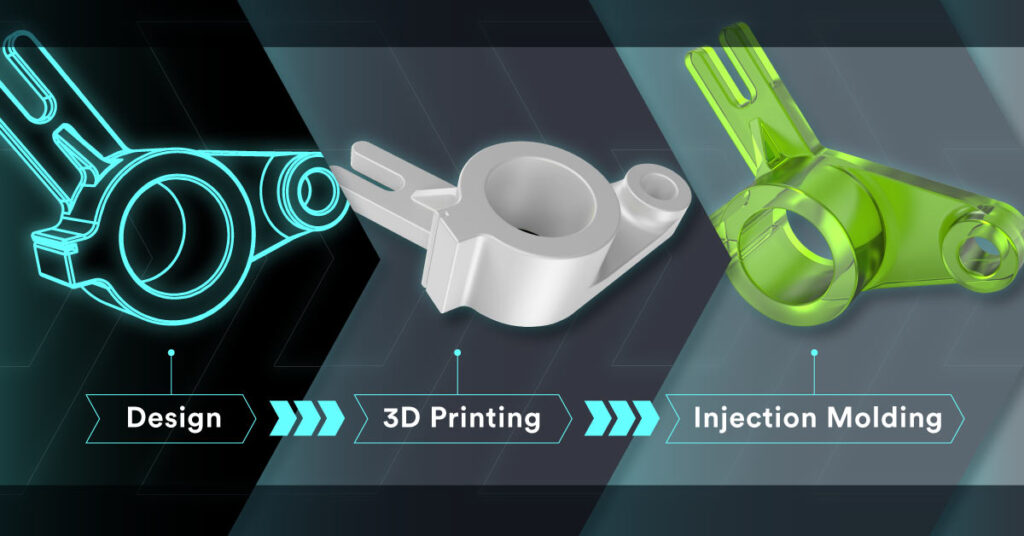

Save on Mould Costs

We’re giving up to $500 off your mold for any part that you previously created with us using 3D printing for a limited period.If you have a large quantity of products, we will make molds for free.

Quality and Reliability

Combining in-process controls and inspections with dimensional verification after production is necessary to reliably produce molded components of excellent quality. The first step in making sure a molded part is of high quality is to design it with the production process in mind. For this reason, we include a design analysis in every quote for injection molding. Early manufacturing analysis can reduce the need for expensive redesigns, shorten the time needed for development, and remove any uncertainty from the molding process. You will learn whether your design has to be changed before placing an order, receive suggestions to make it more moldable, and view other helpful information to comprehend how the finished component will be formed.

GD&T for Injection Molding

We have expanded the range of dimensional verification options we provide you by including GD&T in addition to our internal first article inspections (FAIs) and process capability assessments.

Injection Molding Materials

We can offer more than 100 different thermoplastic materials. If you are looking for alternative materials, please review our resin substitution guide for ABS, PC, PP,POM,PA,PBT,PPS and other common plastics, or contact us.

Thermoplastics

What Is Injection Molding?

Injection molding is a manufacturing process in which molten plastic is placed into a metal mold tool. The tool consists of two parts, the core and the cavity. The plastic is injected into the mold to create a part with the desired form. The finished product is typically made of a thermoplastic resin.

Why Choose Us for Custom Injection Molding?

1.Preferential support

Get custom plastic molded prototypes and production parts in as few as 7 business days. We provide expert engineering reviews and $500 off your first mold.

2.Great Support

One-stop service from materials to logistics

Built in house mold service

Absolutely necessary English engineering communicationandDFM support.

3.Competitive price

Our factory is in Ningbo, the hometown of molds in China, which is the production base of molds and plastic products in the whole China. The price is more affordable and the technology is more professional. It is close to the port and most suitable for trade

4.More comprehensive service

We have supporting equipment and machines, from designing, manufacturing molds, mass production, 100% inspection process, and having more complete other cooperative suppliers, such as 3D printing, spray painting, silk screen printing, film injection molding and other services

5.Custom and spot

We have a full set of customized plastic parts service, as well as the supply service of off-the-shelf plastic parts, you can contact us for consultation

6.Experienced Team

Our technical staff have been engaged in the injection molding industry for more than 10 years, so we are more professional

Advantages of Injection Molding

Advantages of Injection Molding

Injection molding is a two-stage process. It uses highly compressed plastic, which is then cooled in a metal mold.

Compared to other molding methods, injection molding offers higher quality and tighter tolerances. Another advantage of injection molding is that it is very fast and efficient. Machines can run around the clock, allowing for rapid production.

Surface Finish List

⭐ Spray painting

⭐ Silk-screen

⭐ Transfer-printing

⭐ Electroplating

⭐ Laser etching

⭐ Anodizing

⭐ Scouring/brushing

⭐ High glaze

⭐ UV-finish

⭐ Embossing

⭐ Polishing

⭐ Cleaning

⭐ Bake finish

⭐ Fuming PC

Injection Molding FAQs

Because of the initial capital investment in tooling, injection molding makes sense for higher volumes of parts. Our mold cost starts at $1,000 and will vary depending on part geometry and complexity. Other factors that will impact injection molding cost are lead times and material.

We manufacture molds, in fact, we are a one-stop factory from product design to mass production of plastic products.

We have two kinds of production molds, one is the simple mold only takes about 10 days, the product material for this is limited to ABS and PA, but it is disposable, the other mold is the regular mold, according to the material and process to determine the time, generally between 25 days to 30 days.

We have fully automated machines and machine assistants that can work 24 hours a day, so you don’t worry if you need to produce very large quantities of products.

The Latest from Xiao Lin Blog:

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …