A recent Nike advertisement discusses the way that the world’s leading brand of sneakers and apparel develops new products for shoes through “continuous refinement…Use, observe, design, build, test, fail, repeat.”

The description is a great description of the build-test-iterate method that most of our agile customers in product design and engineering utilize to rapidly develop new products to meet the market’s needs. They accomplish this through this process known as New Product Introduction (NPI) often referred to as New Product Development (NPD).

We have clients from many different industries, as the various phases of product development are focused on speed. What can you do to develop products faster, create the most suitable parts quicker and gain feedback from customers as you work on your initial ideas, and then flip around and develop more versions of your product, again faster. Digital manufacturing techniques provide the speed that we discuss in greater detail in our latest report on creating a strategy for your product. Alongside the speed, our customers also require high-quality standards and control, along with quality inspection systems present throughout manufacturing and prototyping processes.

This blog post will explain the concept of NPI is and what it takes to creating refinement, testing, launching, and validating the first product on the market.

What is NPI?

New Product Introduction (NPI) or New Product Development (NPD) is the process of establishing an action plan for taking the idea of a product from its initial concept to its final, ready-for-market version.

The process begins with preliminary studies and market research that relate to a specific idea or requirement and then progresses to proof-of-concept prototyping. After that, engineering and design phases take place simultaneously. After that, validation or verification testing as well as production validation Quality testing, and the final step is to ramp up to production in mass.

NPI as well as NPD are terms used by many, if certainly not all industries to define or define the process in some manner. The degree of detail in specific industries may differ. For instance aerospace, medical and automotive industries will be more involved in the verification processes due to the requirements for compliance in the industry and the sheer complexity of the products produced. Let’s examine these steps one by one.

Research, Market Data, and a Business Plan: An NPI Prequel

Prior to beginning the NPI as well as the NPD process is initiated the company must first try to figure out what problems customers are looking to solve. The requirements of customers, the end customers–are examined more thoroughly in this phase. The company then undertakes research, and study information on the market that relates to the question of whether a brand concept or product that is new is necessary or feasible.

Based on this study, a product manager general manager, product manager, or even the founder of a new business, will draft an initial plan that ultimately will be an business plan. It is then approved to move forward.

Proving and Defining Key Concepts, Feasibility for NPI

The study and business plan will eventually lead to this start stage, a proof-of-concept prototype. The company will be looking to determine whether the concept is viable. A CAD model in software depicts the idea and the components. The actual manufacturing and the materials currently used are for prototypingpurposes: cardboard, foam, duct tape and in some instances desktop 3D printing.

Design and Engineering Development

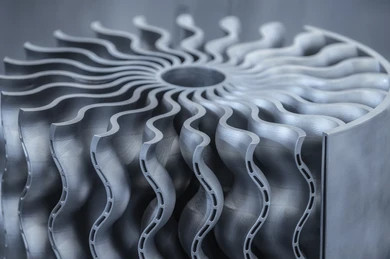

Engineering and design collaborate at this point, using speedy prototyping–aided by digital manufacturing speed naturally–to create two types of concepts. The concept of design can be described as an idea that “looks like” prototype, focused on its aesthetics and commercial appeal, while looking also at the cost time, lead times, and manufacturing capabilities. Concepts for engineering are “works like” prototype, with a focus on the functionality of the product and how it can be used. Testing is currently underway for the Alpha version. At this point, 3D printing (aka additive manufacturing) and sheets of metal, and CNC machining is used to build prototypes.

Man inspecting machine

Engineers check the settings on his CNC mill before machining parts.

Engineering Validation Testing (EVT) for NPI

This is when injection molding is a factor, since”looks like” and “looks like” and the “works like” prototypes are put together using the final, end-of-use production material. It is crucial to make important decisions at this point like what material is used in the product and what manufacturing process is used depending on the amount required. For instance, if 100 items are needed, 3D printing might work perfectly, however when thousands are required the molding process will be utilized. This is also the time when product designers employ the design for manufacture (DFM) procedure to confirm the engineering elements of the product and also helps evaluate cost-saving trade-offs. In this stage, product developers can perform iterations to test and validate different designs material, configurations, and so on.

Design Validation Testing (DVT) for NPI

This is when all the specifications for the design are verified by examining the requirements of customers. This DVT process ensures the product will meet the specifications that were established earlier in the process. Once the design is ready to be produced, as well as the design is locked. Furthermore an aspect of quality engineering is incorporated into this process which includes the typical quality checks: the first inspection of the product Quality documents, quality audits and other such things. While quality engineering is mentioned in this article but it is, in reality, a component which is integrated into the entire process.

Production Validation Testing (PVT) for NPI

The most important part of PVT involves testing the mass production yields using one nearly-finished production-ready design. It’s an issue of scaling. We are near getting ready for final production. This involves transferring the prototyping phase to manufacturing. This procedure involves working through the “boxes” that need to be completed prior to going into production.

Ramping Up to Mass Production

It’s basically the final stage. It’s a final look at the details before going to market with the mass production of the product. As a manufacturer that is digital and on demand we can help you in the process of ramping up too. With us, you’ll be able to purchase parts on demand, with no minimum quantity orders (MOQs). This idea that manufactures on demand will help you to control the market’s volatility, and you’re not tied to huge production forecasts. If the demand increases it is possible to get the parts in a short time, eliminating the chance of losing sales opportunities due to delays in delivery or stock shortages. times. On-demand source also lowers overall inventory costs and warehousing costs.

As you can see, the NPI or NPD procedure is used across a wide range of industries for creating and building for new product ideas. Additionally, the most important aspect of the success of an NPI procedure is its speed. This permits rapid prototyping while engineers and product designers progress along the way.