Injection molding is a process that uses heat and pressure to create plastic objects. It is one of the most common ways to mass produce plastic parts, and it’s used in a variety of industries. Some examples include automotive, home goods, medical devices, and packaging. In this article, we introduce you to the basics of injection molding as well as its variations. We’ll also discuss common materials used in injection molding, the different types of molds used for this process and some of the pros and cons of this manufacturing technique.

What is injection molding?

Injection molding is a process that uses high heat and pressure to create plastic parts. It is the most common way to mass produce plastic parts, and it’s used in a variety of industries. Some examples include automotive, home goods, medical devices, and packaging. There are three main steps in the injection molding process. First, raw materials are prepared by mixing them with other additives (colorants, antioxidants, etc.) to get the desired properties. This mixture is then heated to create the molten state needed for molding. The last step is to inject the molten plastic into a mold where it cools and takes shape. This mold is designed to look like the final product, so when the plastic cools, it retains its shape. This shape is then removed from the mold so the product can be used.

How does plastic injection molding work?

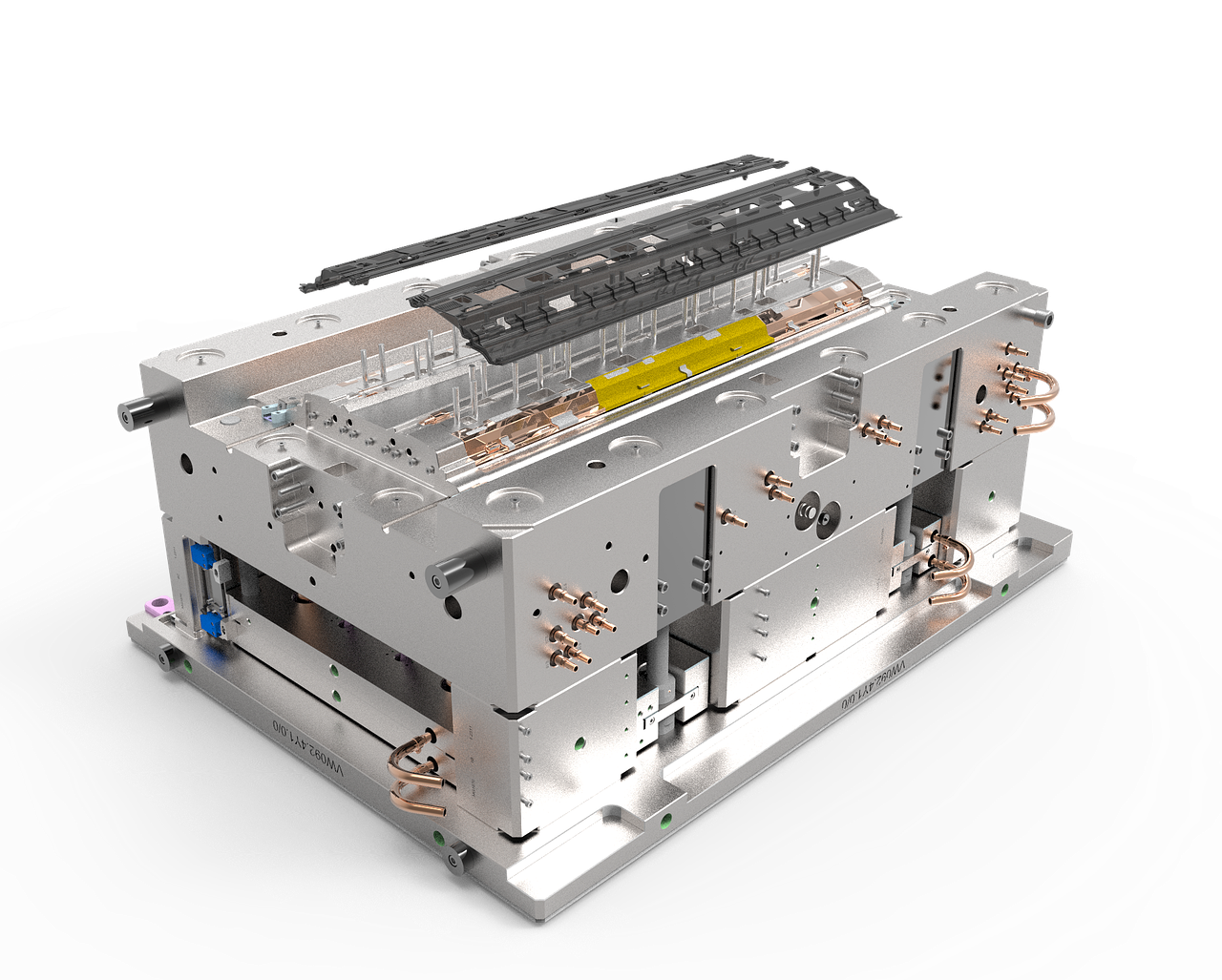

The injection molding machine is made up of a hopper, a screw (or auger), a heating element, a cooling device, a pressure device, and a mold. Raw materials like plastic pellets or powders, together with a resin or a chemical binder, are fed into the hopper. The screw or auger rotates and moves forward towards the heating element. Here, the feedstock is heated up to a temperature suitable for the molding process. The auger then moves it towards the cooling device, where it is cooled down to room temperature. After the feedstock is cooled, it moves towards the pressure device, where it gets pressurized by the help of a plunger or pressure screw.

Variations of the Injection Molding Process

There are three main variations of the injection molding process: – Hot runner system: This is one of the most common variations of the hot-molding process. It uses a single-spray nozzle and a single-cavity mold. The flow of the molten plastic is controlled by gates or sprays that are positioned at the back of the mold. This variation is used for all types of resins, but it’s particularly helpful when working with materials that are difficult to flow. – Cold runner system: This variation of the injection molding process is suitable for brittle materials, as it doesn’t use heat. Instead, it uses a plunger to force the molten plastic into the mold. The molten plastic is cooled down by a cold runner system. – Warm runner system: This variation of the injection molding process uses a single-spray nozzle and a multi-cavity mold. The flow of the molten plastic is controlled by the help of a hot runner system that is positioned at the back of the mold. This variation is suitable for materials that are difficult to flow, and it is also used for large parts.

Materials used in injection molding

When selecting a resin for molding, a lot of factors need to be considered. Some of them include viscosity, flow rate, thermal properties, and chemical resistance. Viscosity: Viscosity refers to the flow rate of a material. A high-viscosity resin is a good choice for creating a strong, solid part — for example, a garden chair. However, a low-viscosity resin is suitable for creating a softer or flexible part — for example, a garden hose. Thermal properties: The thermal properties of a resin refer to its ability to withstand high temperatures without disintegrating. A resin with high thermal resistance is suitable for creating molds for parts that are used in high-temperature environments — for example, car parts or machine tools. Chemical resistance: A resin’s chemical resistance refers to its ability to withstand certain chemicals without decomposing. Resins with high chemical resistance are suitable for creating molds for parts that come into contact with harsh chemicals — for example, medical devices or packaging equipment.

Types of molds used in the injection molding process

There are several types of molds used for the injection molding process. Each one is designed to create specific products, although there are some that are suitable for a variety of applications. – Standard mold: A standard mold is suitable for creating parts with flat surfaces. It’s suitable for producing small batches of parts, and it can be manufactured quickly. – Warm mold: A warm mold has a curved surface and is used to create parts with a curved or round surface. It’s suitable for creating large parts that have similar wall thickness throughout. – Hot runner mold: A hot runner mold is used to create molds that have a complicated shape. They are used to create large parts that have a large wall thickness. – Cold runner mold: A cold runner mold is suitable for creating molds that have a complicated shape. They are used to create large parts that have a large wall thickness.

Pros and cons of the injection molding process

Pros: – Economical: Injection molding is an economical process that can produce large batches of parts quickly. – Diverse applications: Injection molding is suitable for creating a wide range of products, from car parts and medical devices to packaging equipment and garden tools. – Consistent quality: Injection molding produces consistent quality parts, which makes it suitable for creating parts that require high precision. – Durability: Injection molded parts are durable and reliable. Cons: – High initial investment: Injection molding requires large upfront investments, including the purchase of equipment and molds. – Challenges with design: Injection molded parts can be difficult to design if they require high precision as the process doesn’t allow for changes once the mold is created. – Limited color options: With the exception of transparent resins, most materials used in injection molding aren’t suitable for coloring.

Key takeaway

Injection molding is a process that uses high heat and pressure to create plastic parts. It is the most common way to mass produce plastic parts, and it’s used in a variety of industries. Some examples include automotive, home goods, medical devices, and packaging. There are three main steps in the injection molding process. First, raw materials are prepared by mixing them with other additives (colorants, antioxidants, etc.) to get the desired properties. This mixture is then heated to create the molten state needed for molding. The last step is to inject the molten plastic into a mold where it cools and takes shape. This mold is designed to look like the final product, so when the plastic cools, it retains its shape. This shape is then removed from the mold so the product can be used. The injection molding machine is made up of a hopper, a screw (or auger), a heating element, a cooling device, a pressure device, and a mold. Raw materials like plastic pellets or powders, together with a resin or a chemical binder, are fed into the hopper. The screw or auger rotates and moves forward towards the heating element. Here, the feedstock is heated up to a temperature suitable for the molding process. The auger then moves it towards the cooling device, where it is cooled down to room temperature. After the feedstock is cooled, it moves towards the pressure device, where it gets pressurized by the help of a plunger or pressure screw.