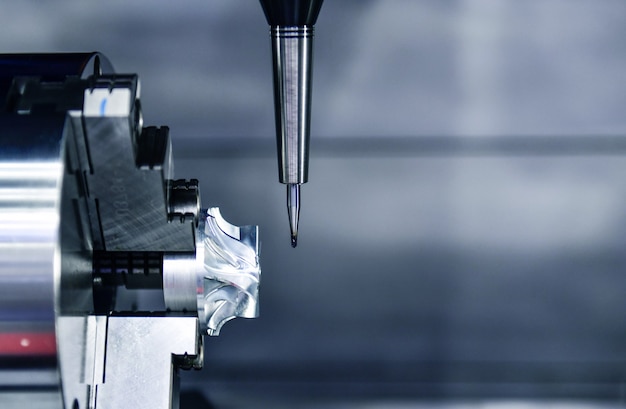

Computer numerical control (CNC) machining is a computer-driven machine tool that is used to cut and shape different materials into different parts. CNC machines are able to do this because they have various sensors and software that allows them to understand exactly what the user wants them to do, as well as give it instructions on how exactly to do it. This article is your complete introduction to CNC Machining from its history, advantages, applications, and more!

What is Computer Numerical Control (CNC) Machining?

Computer numerical control (CNC) machines use computer software to control their actions, including the cutting and shaping of materials. CNC machines are used to produce a variety of parts, including parts used in the automotive industry, aerospace industry, and many other industries. CNC machining is used to produce parts with accuracy and precision. CNC machines are able to do this because they have various sensors that detect the machine’s position and various instructions that allow them to understand exactly what the user wants them to do, as well as give them instructions on how exactly to do it. CNC machines are able to produce accurate parts because they are programmed using computer software that allows users to input data such as toolpaths, feeds, speeds, and more. Because of the high accuracy and precision that CNC machines are able to achieve, they are widely used in production environments.

Why Should You Learn CNC Machining?

Computer numerical control (CNC) machines have become very popular in recent years because they are able to produce parts that are very accurate and precise. CNC machining is used to produce parts in many fields, including the automotive industry, aerospace industry, and many other industries. CNC machines are used to produce a variety of different parts that are used in different machines, such as parts for engines, machine tools, and even medical devices. You might be wondering why you should learn about CNC machining. Here are some of the most important reasons why you should learn about CNC machining. – You will be able-to succeed in the manufacturing sector – CNC machining is used in the manufacturing sector to produce parts for many different machines. After learning about CNC machines, you will be able to succeed in the manufacturing sector and learn about many different machines. – You will be able to succeed in the engineering sector – After learning about CNC machines, you will also be able to succeed in the engineering sector and learn about many different machines. – You will be able to succeed in the medical sector – You will also be able to succeed in the medical sector and learn about different medical devices that use CNC parts. – You will be able to succeed in the aerospace sector – You will also be able to succeed in the aerospace sector and learn about different aircraft that use CNC parts. You will be able to succeed in all of these sectors by learning about CNC machines.

Differences between CNC and Manual Machining

Numerical control (NC) and manual machining are two different methods that are used to produce parts. CNC machining is a computerized process that is controlled by software. With CNC, a user can input a program that tells the computer what to cut out of the material, where to move the machine, and what tools to use. Manual machining is the process of using tools to shape a workpiece by hand. A workpiece is a part that is being made. CNC machining is a computerized process that is controlled by software. Manual machining is a process that is done without computer assistance. CNC machining uses a computer to control the machine. Manual machining does not use a computer and is done by hand. CNC machining is done with the help of a computer. Manual machining is done without the help of a computer. CNC machining uses a computer to control the machine. Manual machining does not use a computer and is done by hand. CNC machining uses a computer to control the machine. Manual machining does not use a computer and is done by hand. CNC machining uses a computer to control the machine. Manual machining does not use a computer and is done by hand.

Applications of Computer Numerical Control Machining

Computer numerical control (CNC) machines are computer-driven machine tools that are used to cut and shape different materials into different parts. CNC machines are able to do this because they have various sensors and software that allows them to understand exactly what the user wants them to do, as well as give them instructions on how exactly to do it. CNC machines are used in a variety of different applications. From the aerospace industry to the automotive industry and many other industries, CNC machines are used to produce different parts that are used in different machines. CNC machining is used in a variety of different industries to produce parts for many different machines. From the aerospace industry to the automotive industry and many other industries, CNC machines are used to produce different parts. CNC machines are used in a variety of different applications. From the aerospace industry to the automotive industry and many other industries,

Conclusion

Computer numerical control (CNC) machining is a computer-driven machine tool that is used to cut and shape different materials into different parts. CNC machines are able to do this because they have various sensors and software that allows them to understand exactly what the user wants them to do, as well as give it instructions on how exactly to do it. CNC machines are used in a variety of different industries to produce different parts for different machines. From the aerospace industry to the automotive industry and many other industries, CNC machines are used to produce different parts. CNC machines are used in a variety of different applications. From the aerospace industry to the automotive industry and many other industries, CNC machines are used to produce different parts.

Of course, in many cases, you don’t need to do these things yourself, you can find excellent suppliers to do them, just like XIAOLIN is a factory specializing in the production of cnc products, I believe it will be helpful to your products.