If you’re considering plastic injection molding, there are a few advantages you should know about before getting started. For starters, the process is much faster than 3D printing, CNC machining, or traditional machining. The typical injection molding cycle lasts between ten and sixty seconds, depending on the complexity of the part. The process is especially efficient when several smaller parts are combined into a single mold. This maximizes efficiency and makes it possible to create hundreds of identical parts per hour. Another advantage of injection molding is its repeatability and reliability.

Compatibility

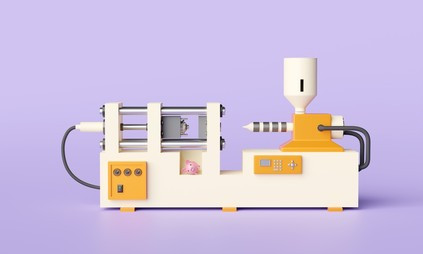

Injection molding is a versatile manufacturing process that is well-suited for mass production. The process involves injecting molten thermoplastics into a durable metal mold and ejecting the finished product once it has cooled. This allows for the production of many identical components in a short time while maintaining high quality and reliability.

One common problem relates to material compatibility. Injection molding machines can handle high temperatures and pressures, but workers should always check their equipment for safety. In particular, they should make sure that the nozzle tip mates with the sprue bushing. Another important safety concern involves using a purging compound when switching resins. Resins that do not mix well can result in an unpleasant experience.

Compatibilities between polycarbonate and polypropylene may be improved by using compatibilizers that reduce their incompatibility. Some studies have also suggested that adjusting compatibility between the two polymers can improve foamability. This may be due to increased phase adhesion between the two resins. This could result in a finer and denser cell structure.

Flexibilit

One of the benefits of injection molding is its flexibility. It can produce parts that would be too difficult or expensive to produce through other methods. Another advantage is that it can produce parts that are extremely complex. This includes parts with irregular shapes and contours. Depending on the complexity of the part, this process can produce parts with very high tolerances.

Injection molding is a flexible process, but its tolerances can be extremely strict. The normal tolerance is +/ 0.005 inches, while the “tight” tolerance range is even tighter -.002 inches or.001 inches. Obviously, the tighter the tolerance, the more expensive the part will be, but finding the right tolerance is essential for producing parts of high quality at a reasonable rate.

Two-component molding

Two-component injection molding involves the injection of two components into a mold. The first part is a base material. The second is a product. The base material is then injected into the second part. The two-component injection molding process is very similar to single-component injection molding, but involves two different materials. The difference is in the way the two materials are molded.

The two-component injection molding process is characterized by high levels of technical expertise and high attention to detail. Any mistakes could be very costly, especially in high-volume production scenarios. For this reason, it is important to have a defined process and contingency plans. It is also important to involve the molding process early in the design phase, so that any potential problems can be identified and solved before production begins. In this way, the company can engineer value into the product.