China has emerged as one of the most important players in the global manufacturing industry. With its relatively cheap labor, direct investment, and other factors, China has become a top-noted manufacturing hub. Among various processes and systems used for manufacturing in China, computer numerical control (CNC) machining is one of the most popular techniques. The demand for CNC machine services continues to increase globally with the growing volume of end users who need CNC machined parts for industrial applications. CNC machining is a computer-assisted process that uses computers to control machine tools to make precise cuts on a piece of material or stock. This article covers everything you need to know about this process and how you can implement it in your business.

What is CNC Machining?

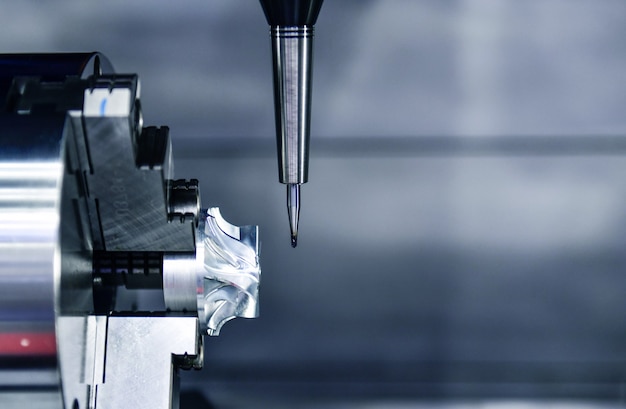

CNC stands for computer numerical control – meaning that a computer is used to control the machine. This process uses computer software to design, cut, and shape different types of materials like metals, plastics, and wood. CNC machining is used for multiple purposes in industries. It can be used to cut down the time and cost of manufacturing complex parts. CNC machining can also be used for architectural applications for designing buildings, interior designing, landscaping, and engineering projects. CNC machines are used to create components that are used in products like cars, medical devices, agricultural equipment, and aerospace equipment. CNC machining has become a popular method of manufacturing parts due to its ability to make extremely precise parts. In general, CNC machining is a process that uses computer software to control the machine tool to make precise cuts on a piece of material or stock.

Why implement CNC machining in your business?

There are many reasons why you may want to implement CNC machining in your business. CNC machines can be used to make precise and complex parts with accuracy. The parts will have precise dimensions and will be consistent across different parts. CNC machines are versatile and can be used to make different types of parts, including intricate and complex parts. CNC machines can be programmed to make identical parts for mass production. If you have customers who want to buy products in large quantities, you can use CNC machining to save money and time. If you run a business in which you need custom parts, you can use CNC machines to create them. CNC machining can be used to make parts from a variety of materials including aluminum, steel, and plastics. CNC machining can be used for a variety of applications such as architectural applications for designing buildings, interior designing, landscaping, and engineering projects. It can also be used for manufacturing applications in industries such as automotive, agricultural, construction, aerospace, and medical.

Step by step process of CNC machining

There are different steps involved in the CNC machining process. Before you start the process, you will need to prepare the design of the part that you want to make. The design can be created in software such as AutoCAD and other computer software. You will also need to create a code for each part that you want to make. Once you have created the design for the part and created a code for the part, you will need to load the part into the machine. The machine will cut the part using the code and the design. Once the machine is done cutting the part, it will eject the part from the machine. You will have to check the accuracy of the part and make any necessary adjustments. Once you are satisfied with the accuracy of the part, you will need to clean the machine and prepare it to make the next part.

Finding a Reputable CNC Machining Company

To find a reputable CNC machining company in China, you will first have to come up with a list of potential companies. You can start your search by talking to people who are already using CNC machining services. You can also talk to agencies and brokers who specialize in connecting businesses with CNC machining companies. Once you have come up with a list of CNC machining companies, you will have to shortlist a few of them based on your requirements. You can shortlist these companies based on their location, reputation, experience, and other factors. Once you have shortlisted a few of them, you will need to contact each of the CNC machining companies. You can talk to them about your requirements and ask them if they are able to meet your requirements. Once you have contacted each of the CNC machining companies, you will need to evaluate each one of them. You can evaluate each company based on their location, reputation, experience, and cost. Once you have evaluated each of the CNC machining companies, you will need to select one that meets your requirements and has the best price. You can also negotiate with them to get the best possible price.

XIAOLIN Plastic Industry Co., Ltd(XIAOLIN) has 18 years of manufacturing experience, we are an experienced manufacturer for custom rapid prototyping, mold, and OEM engineering & manufacturing in Zhejiang, China.

Our products have widely served in the market of medical appliances, automotive, household electrical appliances, aerospace, industrial machinery, and other fields through advanced processing technologies of Precision CNC machining, Injection molding, Die making, and 3D Printing. At XIAOLIN, you could find an ideal production way for your design based on tolerance, size, quantity, and lead time. Send your question to us and get a free quote for your project now.

Conclusion

CNC machining is a process that uses computer software to control the machine tool to make precise cuts on a piece of material or stock. This process is used for designing and manufacturing components in industries. The demand for CNC machine services continues to increase globally with the growing volume of end users who need CNC machined parts for industrial applications.