Online 3D Printing Service for Custom Parts

Plastic prototypes and on-demand production parts using digital manufacturing. Ask for a price on injection molding right now.

1.4 Million

Parts molded each month

10,00+

Product developers served

100+

Plastic materials

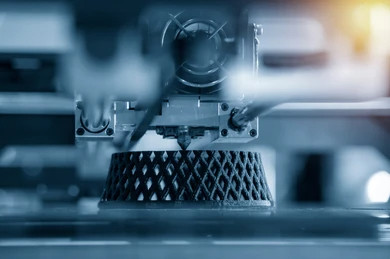

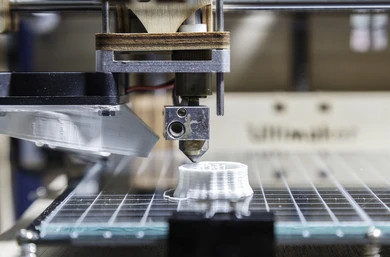

3D Printing Processes

3D printing is a method for manufacturing objects from digital files. These files can be generated by scanning an object or by computer-aided design drawings. A 3D printer produces objects from these files by depositing successive layers of material. 3D printers vary in their approaches to printing and the types of materials used.Our online 3D printing service includes three 3D printing technologies to convert your 3D files into plastic and metal parts. We have an unmatched ability to reliably deliver parts within days.

SLM 3D Printing

We use SLM (Selective Laser Melting) to print metal parts. The metal powder will be melted and formed layer by layer to

build the part.

3D printing manufacturing reduces material waste and enhances the flexibility of the design.That’ s why metal printing to be a popular alternative to machining services.

SLS 3D Printing

SLS (Selective Laser Sintering) printing

fuse the powder (typically nylon powder)

to form the part by laser technology.

Without additional supporting materials,

the SLS printed parts allow high flexibility

and are very suitable for functional parts

and moving parts from prototypes. Parts

can be assembled or jointed.

SLA 3D Printing

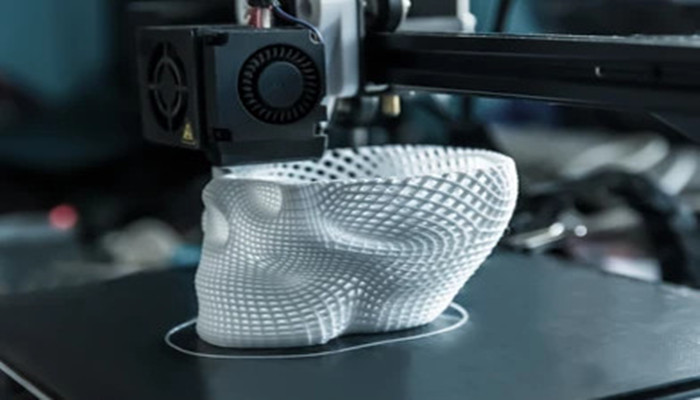

SLA (Stereo lithography Appearance) printing is applicable to presentation prototypes, concept models, and translucent prototypes. To create parts, the process cures the photopolymer layer by layer by UV light. SLA technology becomes popular because of the result of high resolution.

What is 3D Printing?

3D Printing is a modern fabrication process that can create 3D printed objects from a variety of materials. Different methods of 3D printing produce different types of parts. Here is a brief overview of these methods.

Available 3D Printing Materials

There are a variety of 3D printing materials on the market. While ABS is a common choice for a strong, durable end product, PLA is more forgiving and works well for rapid prototyping and disposable products. Then there’s ASA, which is similar to PLA but also offers improved UV resistance. This material is ideal for printing complex objects, such as toys and fasteners. Another common 3D printing material is PETG, which combines the printability of PLA with the strength and durability of ABS.

Metal printing is a great option for metal parts. Unlike traditional casting, this process uses metal dust and fires it to harden it. The parts can then be electro-polished and released onto the market. The advantages of 3D printing include its flexibility, speed, and affordability.

Metal-filled filament adds weight and a metal-like appearance to parts made using 3D printers. Metal-filled filaments can be made of iron or steel. Iron is a popular filler, but it can oxidize over time. Copper and stainless steel are also used as metal fillers.

Available 3D Printing Materials

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

- Titanium

Plastics

- ABS

- PA (Nylon)

- PC

- PP

- PLA

Producing high quality products is our goal, professional technology is our foundation, and serving every customer with enthusiasm is our aim

——XIAOLIN

All employees

Common 3D Printing Applications

The aerospace, medical, automotive, and other major industry sectors can all benefit from the quick prototyping and production capabilities of additive manufacturing.

- Housings and enclosures

- Form and fit prototypes

- Medical devices

- Snap fits

- Jigs and fixtures

- Heat exchangers and heat sinks

- Engine components

- Fuel injectors

- Surgical instrumentation

Surface Finish Options for 3D Prints

Unfinished On the bottom of the section, standing “nibs” or dots from the support framework are still visible.

Natural The support nibs are removed from supported surfaces by sanding them down.

Standard For a uniform appearance, supported surfaces are sanded, and the entire portion is gently blasted. The layers are still visible, as you can see.

Custom There are a variety of finishes available, including soft-touch paint, transparent part finishing, painting, masking, color matching, decals/graphics, and texture.

Surface Finish Options for 3D Prints

Looking to improve the durability, precision, or aesthetics of your 3D-printed parts? The options include metal plating, secondary machining, microfluidic and micro-resolution materials, as well as specialized finishes like painting, clear coating, and decals.

Clear Coat Clear cosmetic finish that can be used on materials that are Translucent/Clear like ABS (WaterShed XC 11122) and PC (Accura 60).

Painting The part can be painted with automotive-grade paint after being smoothed out with sanding and polishing.

Plating It is possible to produce pieces that resemble cast aluminum or magnesium using electroless nickel plating.

Machining To satisfy precise tolerances or achieve high surface finish quality, machine metal 3D print.

Heat Treatment Multiple heat treatment methods, including NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging, can harden and strengthen metal 3D prints.

Polishing Parts can be polished to a finish resembling a mirror. If this is a need, we kindly ask that you submit a design or photograph that depicts the level of finish you anticipate.

Advantages of 3D Printing for Rapid Prototyping and Production

Rapid prototyping allows designers to quickly test the functional and aesthetic qualities of their designs. This can be helpful before a design is approved for production. It can also help refine designs that have unique surface textures or unique shapes. By using 3D printing, designers can create multiple versions of a product in a short amount of time, allowing them to make changes without affecting the design process.

Using 3D Printing allows for faster product development, reducing the time to market. The ability to test products faster is especially helpful for manufacturing companies, as it allows them to make adjustments to designs as they go. It also helps improve the durability of the products they produce.

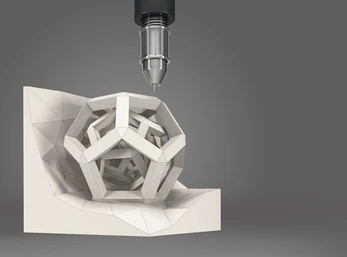

Another advantage of 3D printing is that it eliminates the need for expensive tooling and long waits to get physical prototypes. With 3D printing, an idea can go from design file to physical product in a matter of hours. With feedback from customers and investors, 3D printed products can be refined and improved.

Another benefit of 3D printing is that it enables complex designs to be printed with high accuracy. This is especially useful for small production runs. The process also enables multiple prototypes to be created simultaneously, and once tested, they can be used for production.

Get an Instant 3D Printing Quote

Save on Mould Costs

Upload a 3D CAD file to get an instant quote on your 3D printing design. In our quoting platform, you can see real-time cost implications based on your choice of 3D printing material and resolution level.

3D Printing FAQs

The design, material, technique, and post print procedures all have an impact on the cost per part of 3D printing. The majority of a part’s cost is typically accounted for by post-print processes, particularly when manual work is required.

3D printing is one of the most popular technologies available today. It is a useful tool for product development and user testing. It can also improve the quality and durability of products. It can also reduce design risk. There are many benefits of 3D printing. This article explores four different types of 3D printing technologies. Each type has different pros and cons. It is important to choose the right one for your needs.

The maximum size of the part depends on the bounding box in the 3D printing machine being used. With the advancement in large format printing options, parts with build volumes as large as 31.5 in. x 15.7 in. x 19.7 in. for metal parts and as large as 29 in. x 25 in. x 21 in. for plastic parts.

3D printing has historically been leveraged as a rapid prototyping manufacturing method. With advancements in post-processing options and engineering grade additive materials, 3D printing is often leveraged for end use part production.

Additional Links and Resources

Pressure gauges are essential tools used in a wide range of industries to measure and monitor fluid and gas pressure. When it …

Plastic injection molding has become an invaluable tool for businesses and individuals who have a need for custom parts or products. A …

Plastic injection molding is a versatile and reliable process for manufacturing products of all shapes and sizes. It is used in a …

Plastic injection molding is one of the most widely used processes in modern manufacturing. It is used to produce a variety of …